Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

FRP laminate in bridge strengthening

Bridge Overview

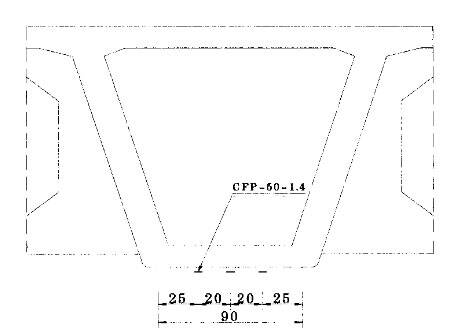

Longtouzui Bridge is an important bridge on the main trunk line of Lianhuo National Road. The length of the bridge is 369.00m. The superstructure form is: a 9x40-meter-span simply supported variable continuous prestressed concrete box girder double-width curved bridge, with a curve radius of 760m. The cross-section of the bridge superstructure is composed of 8 prefabricated prestressed box girder, the girder height is 2.0m, and the flange plates are connected by wet joints. The whole bridge is equipped with three D80 expansion joints, and the prefabricated pre-stressed box girder, cast-in-place beam, and cast-in-place bridge deck concrete are all made of C50 concrete. The design load of this bridge is highway-I level, and the design flood frequency is 1/100.

The inspection unit conducted quality inspections on the bridge and found that there were horizontal and longitudinal cracks in the bottom of the box girder, vertical and horizontal cracks in the web, and irregular cracks at the root of the top flange. In the static load test, according to the relationship between the measured deflection and the load, it is inferred that the beam is basically in an elastic working state under the design load. The residual deformation of individual sections under various working conditions did not meet the design requirements; individual cracks expanded slightly during the load test. The first to third order natural frequencies measured by the pulsation test are slightly larger than the calculated values. The final identification test result is: the beam body is basically in a flexible working state. However, due to poor concrete quality, insufficient concrete strength of the main beam, and poor transverse connection, the strain check coefficient of some control sections is greater than 1.0. The bridge does not meet the requirements for normal use of the designed load, and the safety reserve of bearing capacity is insufficient. It is required to take reinforcement measures and treat the defects.

Main bridge reinforcement methods

Reinforce by pasting pre-stressed FRP laminate on the bottom of prefabricated box girder, and pasting carbon fiber cloth on the web; pasting steel plate on the transversal partition to strengthen the lateral connection between each beam; other defects of the main girder are classified and treated.

The prestressed FRP laminate is pasted on the bottom of the box girder to improve the stress of the bridge, thereby increasing the load-bearing capacity of the girder and achieving the purpose of strengthening and lifting the load.

Prestressed FRP laminate reinforcement technology

By adding 3 pre-stressed FRP laminate to the bottom of the box girder, the rigidity of the girder is enhanced, the development of cracks is suppressed, and the capacity of the bridge is increased.

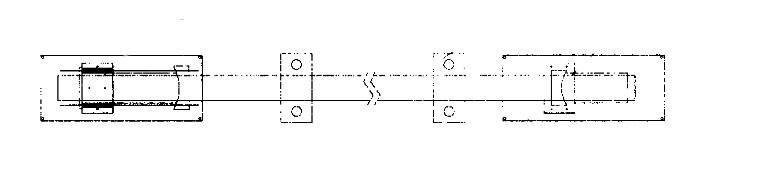

External prestressed anchor system

The external prestress adopts the comparative anchor and fiber composite material prestress construction method. The anchor system is a wave-tooth clamp tension anchor system, which includes anchors, clamps and supporting protective covers. The anchor and the protective cover are respectively fixed to the bottom of the beam by embedding bolts. In order to prevent the prestressed tendons from resonating with the beam body, a special FRP laminate adhesive is used to fix the tensioned FRP laminate to the bottom of the beam to form a whole with the beam body.

Material selection for external prestress

The external prestressed tendons are made of Horse CFRP-50mm-1.4mm first-class carbon fiber laminate, which is 50mm wide and 1.4mm thick carbon fiber laminate.

As a new type of prestressed material, FRP laminate has excellent physical properties such as high strength, light weight, and corrosion resistance, as well as good adhesion and wide applicability. Reinforcing concrete structures with carbon fiber laminate prestressing technology is a new technology that has emerged internationally in recent years.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.