Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

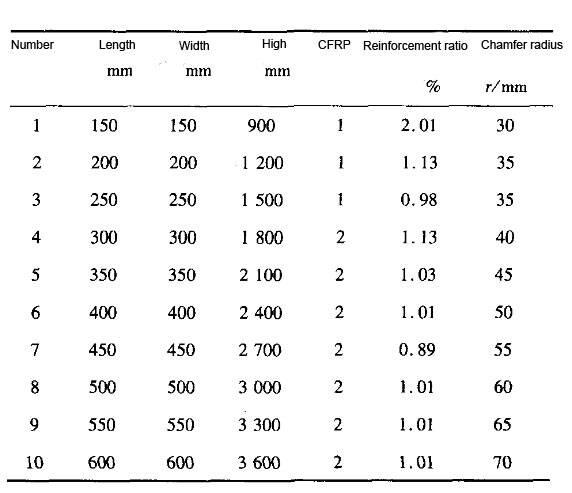

The influence of the size effect on the carbon fiber reinforced axial compression column

The influence of the size effect on the carbon fiber reinforced axial compression column

(1) Reinforcing rectangular columns with carbon fibers can significantly increase the bearing capacity. From the results, it is generally more than 10%.

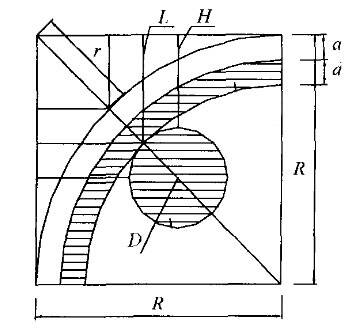

(2) Chamfering has a great influence on the results. It can be seen from the stress that stress concentration has occurred in the corners, and damage occurs in advance. It can also be seen that the effect of the simulated curve is lower than the theoretical value, because the method of polyline approximation is used when chamfering, and the effect is not as good as the circular one. After calculation, the maximum chamfer radius R is about 80 mm, and the actual ruler can achieve 70 minutes. Therefore, the influence of chamfering should be fully considered when calculating the bearing capacity.

(3) The effect of carbon fiber on small models is more obvious, reaching about 30%. As the size increases, the proportion of carbon fiber becomes smaller and smaller, reducing to about 10%. The reason is that the small model has a small bearing capacity, and the restraint effect played by carbon fiber accounts for a larger proportion of the small model. The small model is close to a cylinder after being chamfered, while the large model cannot have a large chamfer radius of the same scale. Therefore, the reinforcement effect of small models is much better, and most of the experiments done are small-scale models, so the results of the analysis should be treated with caution.

(4) It can be seen from the figure that the simulated bearing capacity of the small model is larger than the theoretical value. The main reasons for the analysis are as follows:

(1) The size of the concrete dividing unit is 50 mm, so the longitudinal reinforcement can only be arranged on the four corners. Originally, stress concentration will occur here, and the first failure. Due to the arrangement of the longitudinal reinforcement, the bearing capacity is greatly improved

(2) Due to the chamfering, the small size model is closer to the cylinder, so the carbon fiber cloth acts as a spiral stirrup, which further improves the bearing capacity compared to a simple stirrup.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.