Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Externally Bonded FRP Reinforcement

Externally bonded FRP composite strengthening materials composed of carbon fiber, glass fiber or aramid fiber and appropriate resin are widely used to reinforce concrete structures. The material can be prefabricated into composite panels or shells and then glued to the concrete surface. Alternatively, the composite material can be formed in situ with the fibers in the form of a fabric impregnated with resin and applied to the surface of the concrete.

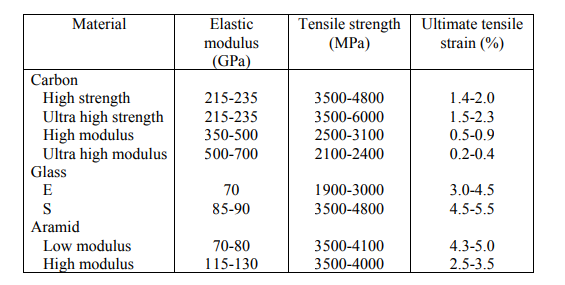

The main advantages of FRP materials are high strength (3000 N/mm2) and light weight (one third of steel). Minimal surface preparation is necessary, installation is simple and fast. Generally temporary support, and the adhesive to gain strength is not necessary. Speed is particularly important for applications such as bridges because of the high cost of owning time. The weight of the structure and the size of the components did not increase significantly. One disadvantage of FRP reinforcement is the possibility of fire, vandalism or accidental damage.

Many concrete structures around the world have been externally reinforced with fiberglass, including bridges, retail and industrial buildings, multi-storey parking lots, lighthouses and cooling towers.

Externally Bonded FRP Reinforcement for RC Structures

The latest developments related to materials, methods and technologies used for structural reinforcement are enormous. One of the most advanced technologies today is the use of fiber-reinforced polymer (FRP) composite materials, which are currently regarded by structural engineers as a "new" material and extremely promising material in the construction industry. Today, composite materials used to strengthen civil engineering structures are mainly provided in the following forms:

Pultruded thin unidirectional tape (thickness approximately 1 mm)

Flexible sheet or fabric made of fibers in one or at least two different directions (sometimes pre-impregnated with resin)

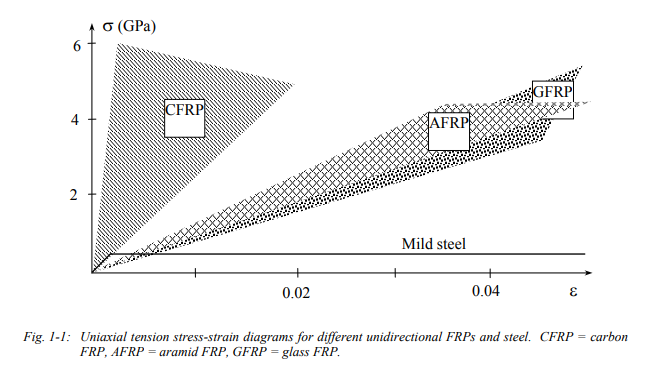

For comparison with steel, Figure 1-1 shows a typical stress-strain diagram of a unidirectional composite under short-term monotonic load.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.