Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

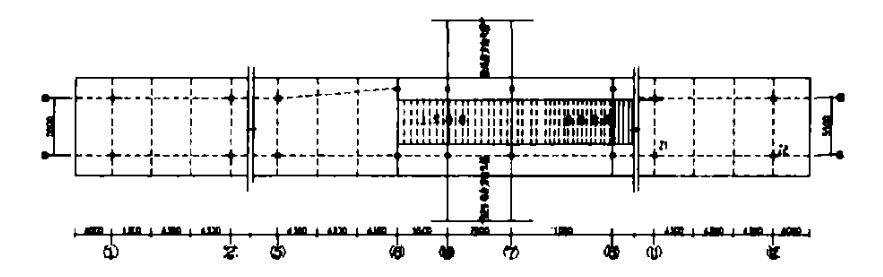

Carbon fiber sheet reinforced railway canopy

Project Overview

The basic platform awning of Wenzhou Railway Station was built in 1998. The soil distribution of the site is as follows: 1. Artificial fill with a thickness of more than 3m. 2. Clay, gray-yellow, gray-brown, yellow-brown, with a thickness of less than 1.0m. 3. Muddy clay, dark gray, flow plastic, thickness greater than 30m, this layer has not penetrated. The original structure foundation is 600 friction-type bored piles, the pile length is 32m, single column and double pile. The maximum settlement at completion is 5mm. According to the basic platform settlement observation data provided by the owner, the maximum settlement (Z2) measured on August 10, 2001 was 336mm. Among them, the differential settlement of the north-south column of the (ll) axis was 120mm, and the inclination was 21.8 per thousand. The differential settlement of the four-axis north-south column is 250mm, and the inclination rate is 46.95 per thousand. The settlement difference has far exceeded the national standard that is 0.003 x 5500 = 16. 5mm. In addition, most of the longitudinal beams have multiple vertical cracks at the mid-span waist, with a width of 0.4-0. 5mm, and a maximum width of 3mm. Some columns have horizontal cracks at the bottom of the beam, which has seriously affected safe use.

Cause Analysis:

1. There are multiple regular cracks in the beams and columns of the platform canopy, which is mainly caused by the excessive and uneven settlement of the pile foundation.

2. The excessive settlement of the pile foundation is composed of the following factors:

1) The large area of the backfill of the site is above 3.0m, (the original geology of the A-axis (ll), the four-axis column foundation is a river course, and the filling height exceeds 4m), resulting in a large-scale settlement of the site. The negative friction resistance of the soil to the pile foundation is the main cause of settlement.

2) The original line roadbed design does not consider the impact of car washing water on the basic platform during use, which leads to the discharge of a large amount of water on the site during use and accelerates its settlement.

3) The original design of the train line and the underpass, the main station building of the railway station, the overpass, and the basic platform canopy were designed by four design units, and the coordination of many design units was not coordinated, and the related designs had a greater cross-effect.

Reinforcement measures

1) Foundation reinforcement and frame correction and lifting plan

Combined with the actual conditions of the geological conditions of the project, the rigidity conditions of the building foundation and the superstructure, it was decided to adopt staggered static pressure piles for foundation reinforcement; to correct the inclination of the awning, adopt the plan of cutting column jacking.

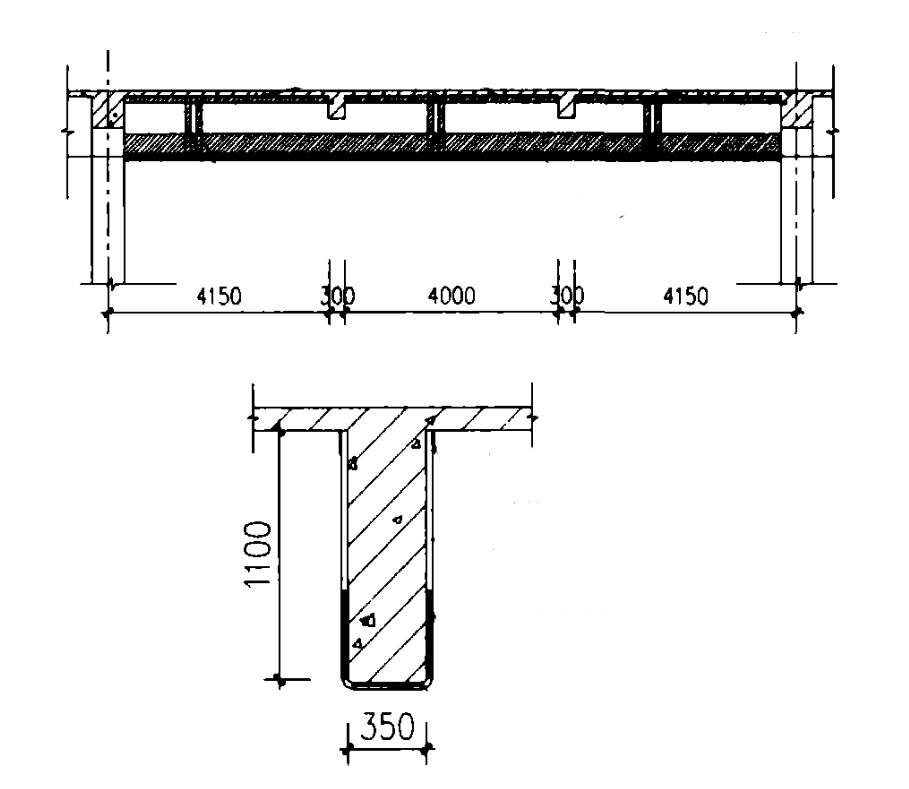

Reinforced concrete frame beam reinforcement

For the frame beam of the rain canopy, the cracks are dense and the crack width is wide, and the carbon fiber sheet is pasted on the surface of the component through the matching bonding material for reinforcement. The bottom surface of the beam adopts two layers of 300-wide carbon fiber cloth and extends to the edge of the support. A layer of 400-wide carbon fiber cloth is pasted on the tension zone on the side of the beam. A layer of 100-wide carbon fiber cloth is pasted on the side of the bottom beam. In order to appropriately improve the shear resistance, one layer of U-shaped carbon fiber sheet 100@200 is pasted longitudinally on the vertical beam, and three strips and three layers are pasted on both ends of the beam and at the concentrated load.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.