Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Bridge beam crack strengthening by carbon fiber reinforced polymer

Overview

Ramp D at South No.6 exit on the downstream side of S32 Expressway is a circular curve with a radius of R=220 m and a cross slope of 5%. Ramp D is a reinforced concrete continuous box girder with uniform cross-section inclined web, with a combined span of 25 m + 25 m + 25 m = 75 m. The single-box single-chamber section, the top width of the box girder is 8 m, the bottom width is 2.88 m, the beam height is 1.7 m, the top and bottom plates are 20 cm thick, and the webs vary in thickness by 30-60 cm. Ramp D cracks are mainly distributed on the surface of the web and bottom plate of the third hole on the east side. The webs are mainly white cracks due to water seepage, and there are serious cracks in the bottom and webs (the crack width w is greater than or equal to 0.2 mm). General cracks (greater than or equal to 0.15 mm, less than 0.2 mm). Slight cracks (w is less than 0.15 mm). The cracks in the bottom plate are transverse cracks that extend to the entire bottom of the box girder. The web cracks are distributed vertically, and the widest part is located at the lower part of the web side beam high school, which develops upwards and downwards, and is connected to the cracks of the bottom plate individually. The width w is 0.1-0.3 mm, and the distance along the bridge is about 50 cm.

Carbon fiber reinforced polymer(CFRP) material reinforcement characteristics

(]) Carbon fiber composite materials are usually composed of carbon fiber and other basic materials, and have good mechanical properties. The tensile strength of carbon fiber composite materials is generally above 3 500 MPa, which is 7-9 times that of steel, and its relative density is less than 1/4 of steel, and it has heat resistance and can withstand high temperatures above 2000 degrees. At the same time, carbon fiber composite materials also have a small heat capacity and excellent corrosion resistance and radiation. Using these characteristics of carbon fiber materials to reinforce concrete structures can effectively improve the bearing capacity, corrosion resistance, and durability of the components, and the self-weight of the structure will not be too burdened.

(2) Carbon fiber is a flexible material with a wide range of applications and various shapes. In some special irregular structures, it can better reflect the advantages of carbon fiber. The molding of this material is also very convenient, can be applied to any part of various structures and components, and does not affect the appearance of the structure.

(3) The relative density of carbon fiber is small and light weight, which also determines that the construction of carbon fiber composite materials is more convenient and simpler, and less space is required for reinforcement. The impact on the operation of the bridge during construction is also small, the work efficiency is higher, and the cost is saved. Take the box girder frequently used in bridge structures as an example. This material can also be used to strengthen the bridge when the internal space is restricted.

(4) The relative density of carbon fiber is less than 1/4 of that of steel. The structure reinforced by this material not only has a small increase in its own weight, but also has no effect on appearance and size. When strengthening the bridge, it is necessary to consider the traffic requirements of the strengthened bridge to ensure a certain clearance. Therefore, compared with the traditional reinforcement technology, carbon fiber reinforcement technology has obvious advantages.

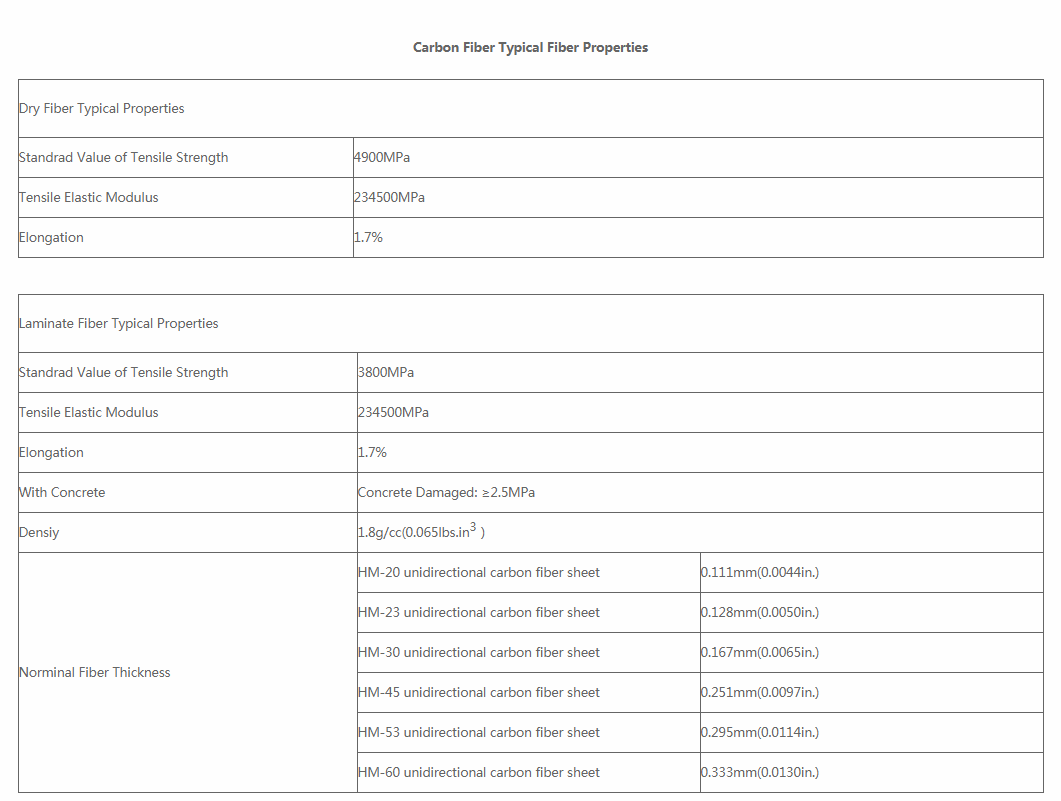

Carbon fiber reinforced polymer(CFRP) performance indicators

Reinforcement process

The solidification process is as follows: concrete surface treatment, adhesive surface repair and leveling (this step can be omitted if it is leveled), primer configuration, primer coating, bonding carbon fiber reinforced polymer(CFRP), curing, inspection, and maintenance.

Conclusion

(1) After the box girder of the south 6th ramp of Shenjiahu Expressway is reinforced with carbon fiber reinforced polymer(CFRP), the cracks on the surface of the girder have a better sealing effect. The carbon fiber reinforced polymer(CFRP) closely adheres to the beam body, and can bear the external force together with the beam body, which improves the stress state of the beam body to a certain extent and extends the structural durability.

(2) In the process of carbon fiber reinforced polymer(CFRP) reinforcement, the treatment of the base layer is very important. The treatment of the base layer directly affects the bonding quality of carbon fiber. The primary treatment requires cleanness, no scum, and levelness. Before using carbon fiber reinforced polymer(CFRP) to reinforce the structure, the surface of the component must be polished, and the corroded and soft concrete must be polished off. After the intact structure layer is exposed, the surface must be trimmed with carbon fiber material. It should be noted that where there are cracks, they must be treated. Common treatment methods include grouting and sealing.

(3) When sticking carbon fiber reinforced polymer(CFRP) materials, pay attention to the quality of the bonding, which is related to the compactness of the rolled material. During the pasting process, rolling must be repeated many times to expel the air bubbles between the materials as much as possible to prevent air bubbles from affecting the quality of the bonding.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

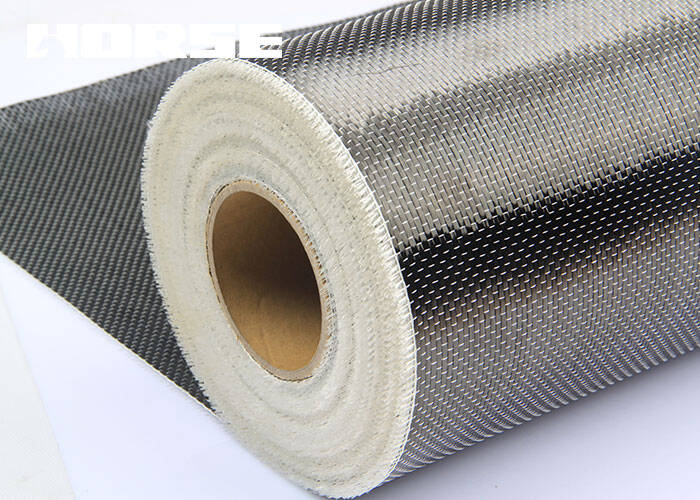

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.