Strengthening And Repair Bridges

Horse Carbon Fiber Wrap

Because the river channel where the bridge is located is an important water traffic channel, if traditional glued steel plates are used for reinforcement, a full scaffold must be built in the middle of the river channel, which will affect water traffic and the construction period will be longer. It is also not suitable to use outsourcing to increase the section size of the component or prestress reinforcement, so consider the use of carbon fiber materials to strengthen the bridge structure.

Project

The span of a bridge is 37m, and the bottom surface of the mid-span beam is about 4.5m above the water surface. It was built in the 1980s. The design bearing capacity is 100t and now it is required to be able to pass the flatbed trailer loaded with the transformer. The flatbed truck has a dead weight of 41t, the transformer weighs 105t, and the total weight is 146t.

Considering that the load far exceeds its design load, theoretical calculations are first carried out based on actual working conditions. This working condition belongs to the load combination Ⅲ in the code: the combination of structural gravity (constant load) and trailer. According to the requirements of the specification, the bridge components are checked and calculated for compression, bending and shearing.

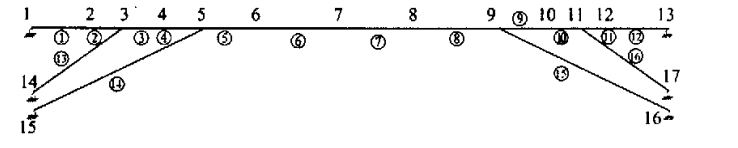

The bridge is an assembled, uniform cross-section, inclined-leg rigid frame bridge. Both ends of the bridge deck are simply supported, the lower end of the inclined leg is hinged, and the upper end is fixed to the bridge deck. Therefore, the mechanical calculation model shown in Figure 1 is selected to divide the full bridge structure into nodes and elements.

After calculation, it is found that under the action of the self-weight of the bridge and the trailer load, the control conditions of the control section can meet the requirements of the specification. However, the oblique shear strength and the shear strength of the joint surface of the three-element 3-node section are insufficient, so it must be reinforced.

Reinforcement plan

Because the river channel where the bridge is located is an important water traffic channel, if traditional glued steel plates are used for reinforcement, a full scaffold must be built in the middle of the river channel, which will affect water traffic and the construction period will be longer. It is also not suitable to use outsourcing to increase the section size of the component or prestress reinforcement, so consider the use of carbon fiber materials to strengthen the bridge structure.

There are two types of carbon fiber used in this reinforcement: one is a plate-like material, which has a hard texture and can be pasted on the surface of the member. It is suitable for the bending reinforcement of beams and is used to improve the bending bearing capacity. Another filamentous material with a softer texture, used for winding or making U-shaped hoop. The glue can automatically penetrate the surface to make the fiber better stick to the concrete. It is suitable for constraining concrete and improving its ductility or shear resistance. . The adhesive is epoxy resin, which is composed of cement, primer, surface glue and curing agent

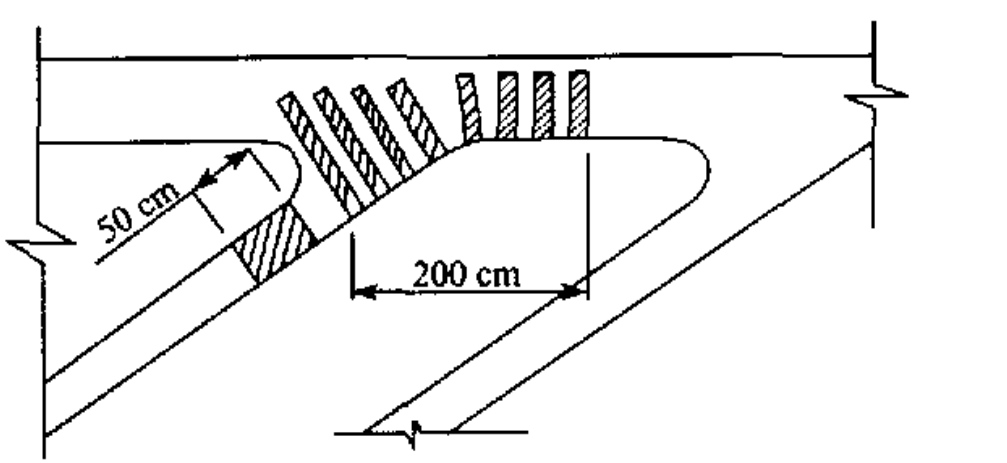

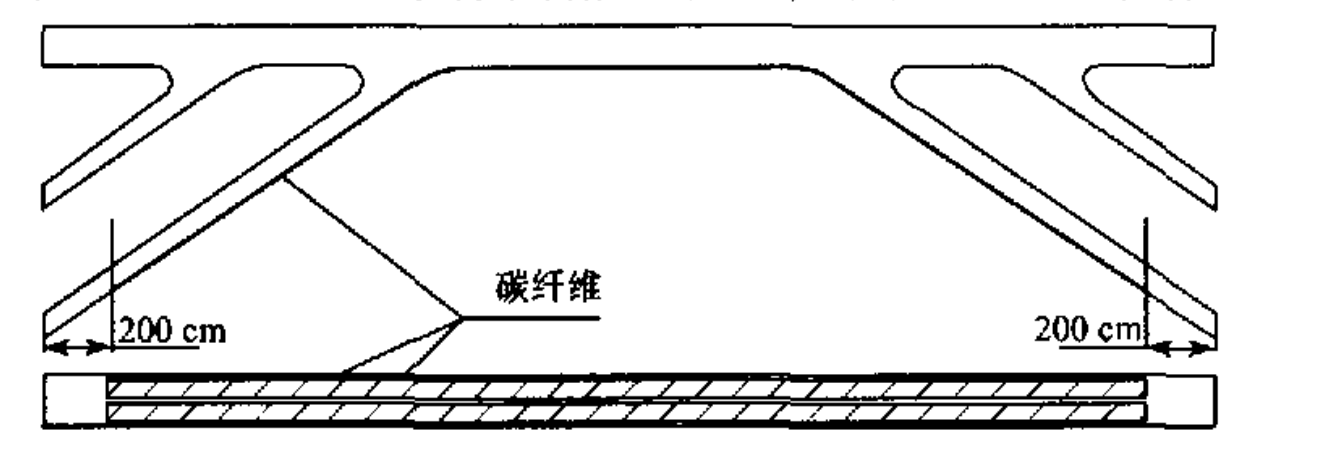

Based on the results of theoretical analysis, it was decided to adopt the following reinforcement scheme for the bridge: first, the inclined beam legs were reinforced, and carbon fiber cloth was wound within 50cm from the 3 nodes to the support to improve the ductility at the nodes. Within 200cm of the 3-node in the mid-span direction, paste U-shaped carbon fiber along the beam to improve the shear resistance of the 3-node, as shown in Figure 2. Then the beam bottom is reinforced with flexural strength, using carbon fiber board, and two pieces of each beam bottom. The starting point starts at a horizontal distance of 200cm from the support and continues to the other end at a horizontal distance of 200cm from the support, as shown in Figure 3. As overweight vehicles crossing the bridge are accidental events, and considering that with the increase of the bridge construction time, the bearing capacity of the piers and foundations will gradually increase, so no other reinforcement measures are adopted for the substructure of the bridge.

Carbon fiber reinforcement bridge

(1) Using carbon fiber reinforcement structure technology to reinforce the bridge, the process is simple, and the construction period is short. After the completion of the project, after inspection and acceptance, it was found that the carbon fiber and the concrete were tightly bound, without hollowing, and no separation. The construction quality of the reinforcement has been well received by the client, and the expected results have been achieved, ensuring the safe passage of overweight vehicles across the bridge.

(2) Because the carbon fiber material is soft and light in weight, the length and width can be determined arbitrarily according to needs, and can be arbitrarily pasted and wound for complex nodes and irregular positions, so it has a wide range of adaptability.

(3) Because carbon fiber materials have strong corrosion resistance, they can be widely used in the reinforcement and repair of structures in special environments