Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Horse Construction: Trusted Epoxy Anchor Manufacturer with Solid Factory Strength

When selecting an epoxy anchor manufacturer, clients prioritize two core factors: proven production capability and reliable product performance. Horse Construction, with its 5,000㎡ manufacturing campus, 8 fully automated production lines, and monthly capacity of 100,000 cartridges, stands as a pragmatic choice for global construction projects. From bridge retrofitting in Southeast Asia to industrial installations in Europe, our factory’s output consistently meets strict quality standards while fulfilling large-volume orders on time.

Factory Strength: The Foundation of Stable Supply & Consistent Quality

Horse Construction’s manufacturing base is designed for efficiency, scale, and precision—addressing the biggest pain points of buyers: delayed deliveries and inconsistent product quality. Our 5,000㎡ workshop is divided into 5 functional zones (raw material storage, mixing, filling, inspection, and warehousing), all equipped with IoT sensors to monitor temperature (25±2℃) and humidity (45-65%)—critical for epoxy resin stability.

Key production equipment includes: 4 sets of high-speed dual-planetary mixers with vacuum degassing (eliminating 99% of air bubbles), 12 robotic filling stations (dosing accuracy ±0.5%), and 3 automatic labeling and packaging lines. These setups enable us to produce 100,000 390ml cartridges and 10,000 30kg barrels monthly.

Every production link is tracked via a digital MES system. Clients can scan the batch code on each product to view its raw material sources, production time, and inspection reports—ensuring full transparency. We strictly control raw material quality by partnering with top-tier suppliers. Each batch of raw materials undergoes 12 pre-test items, including purity (≥99.5%) and viscosity stability, and only those passing all tests enter the production line. This strict sourcing standard directly reduces product defect rates to below 0.01%.

R&D Capability: Driving Product Advancement

We invest 8% of annual revenue in R&D, supporting a 6-person team of chemical engineers and structural specialists. Our lab, accredited by ISO 17025, conducts over 50 tests per batch, including tensile shear strength, aging resistance (1,000 hours of UV exposure), and high-temperature performance (up to 120℃).

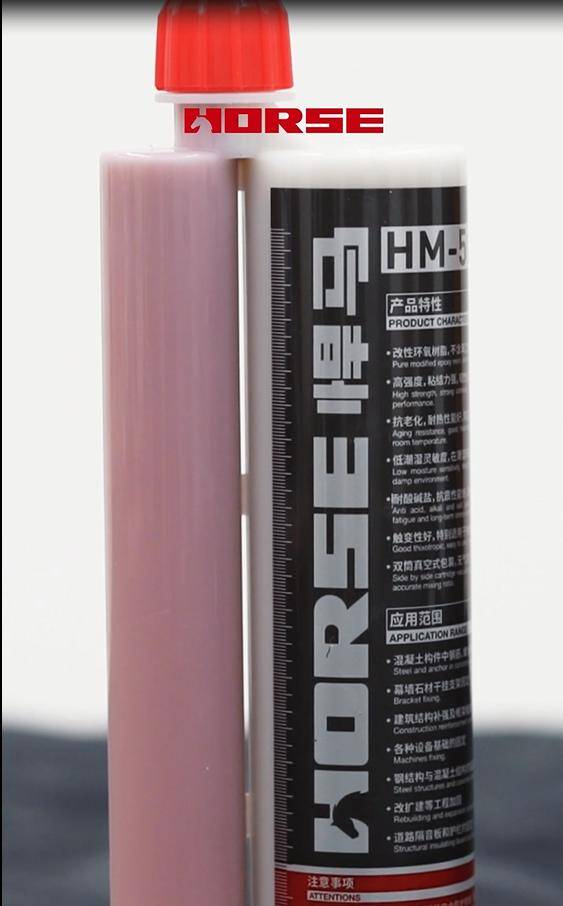

Collaboration with the Chinese Academy of Building Research has led to proprietary formulations. Our flagship HM-500 series, for example, uses modified epoxy resin that cures at 5-40℃ (no need for heating/cooling) and maintains strength in pH 3-11 environments—suitable for coastal projects with saltwater corrosion. The HM-500T variant, designed for industrial furnaces, retains 95% of its strength at 120℃, outperforming competitors’ 70% retention rate.

Product Performance: Practical Advantages for Construction

Our epoxy anchors are engineered for real construction scenarios, with measurable performance metrics:

- Strength: HM-500 achieves tensile strength ≥70 MPa, compressive strength ≥152 MPa—capable of anchoring M36 bolts in C25 concrete without failure.

- Adaptability: Thixotropic formula prevents sagging in vertical/overhead applications (tested at 45° incline for 30 minutes). Performs in dry, wet, or flooded holes—no need to wait for water to dry.

- Efficiency: 3:1 mix ratio (easy to control), 12-hour basic cure (supports formwork removal), 72-hour full cure. Paired with our electric glue gun, installation speed increases by 100% compared to manual mixing.

- Sustainability: VOC-free, non-toxic.

Global Certifications & Client Support

Our products meet global standards: ISO 10485-2018, GB/T 22701-2023. These certifications eliminate import barriers for clients in the EU, U.S., Southeast Asia, and the Middle East.

We provide end-to-end support for international clients: localized TDS, on-site installation training (via video or in-person for orders over 50,000 cartridges), and a 24/7 technical hotline.

For after-sales service, we offer a 2-year product quality warranty—if any quality issues occur due to manufacturing defects, we provide offer solution.

Choosing an epoxy anchor manufacturer is choosing a partner for project safety and efficiency. Horse Construction stands out not for empty slogans, but for verifiable data and proven results that address international clients’ core concerns.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

High-strength anchor bolt with vinyl resin as main materials, composed of selected quartz sands, curing agents and glass tubes

Two-component modified epoxy resin adhesive, applied to chemical planting reinforcing bar and anchor bolt anchoring