Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Can Carbon Fiber Reinforcement Be Started Immediately After Primer?

During the construction of carbon fiber fabric, the concrete component is generally processed with a primer. The first is to initially enhance the strength of the component, and the other is to improve the performance of the glue and prevent pollution or corrosion after the surface treatment of the substrate. Simply put, it is to make the adhesive connector more flat and clean, which is convenient for carbon fiber cloth.

So when will the next step most suitable after applying the bottom? Let's take a look at the complete video of carbon cloth construction:

In the process, what does it mean to mention the word "glue need to be dry"? Why must you roll the impulse adhesive after "dry finger"?

The "refers to dry time" of the bottom glue

The "fingering time" of the bottom glue, that is, the curing time of the bottom glue, the solidification depends on the temperature of the scene, and the fingers should be dry.

Why can the bottom glue be dried before rolling and imply the rubber?

1. "Fingering" is an important construction link. At this moment, the bottom gel has properly gel and loses liquidity, but the surface of the film has not yet passivated. At this time, it is the best time to stick carbon fiber cloth.

2. The grasp of the "Fingering" period should be appropriate and accurate. The correct construction program is to immediately paste the carbon fiber cloth operation when the bottom glue is dry. Premature can cause structural glue adhesives so that the carbon fiber cloth adhesion does not appear empty drums or even fall off. Too late, the surface activity of the glue membrane is reduced to affect the bonding performance.

3. If the degree of hardening of the bottom glue has reached the non -deformation of the finger pressure, it should be waited for 12 hours to complete the gloss or rough surface gloss with sandpaper or corner grinding machine, and then paste the construction of carbon fiber cloth. And apply a fine soft wool brush or clean cotton yarn to dip the industrial acetone before paste to remove the unclean residues and the newly falling dust.

The above is the theoretical explanation of the appropriateness of dry time. From another perspective, we can also reverse from the construction acceptance of the project:

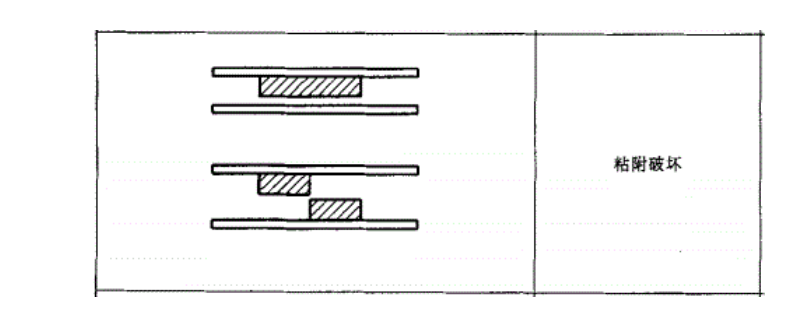

The positive pull -up test during construction acceptance is the most direct and convincing quantitative inspection method, and it is also the final judgment of whether the construction quality is qualified. There is an indicator in the judgment standard -the form of destruction. And we often occur in actual acceptance of abnormal damage -adhesion destruction (interface destruction).

The reason is that the construction of all levels of the bottom glue and fiber paste layer does not follow the standard construction requirements. The primer may be caused by improper treatment after being excessively hardened. It is characterized by the bottom gel layer on the surface of the concrete and the composite material layer and the metal test block are unplugged.

So don't look down on the construction of the bottom glue. If the acceptance is not approved, all the efforts will be east.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Low viscosity, strong penetration carbon fiber primer for reinforced concrete surface to enhace the defect part

Good thixotropy carbon fiber leveling adhesive for concrete surface repairing