Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How Much Does High Temperature Welding Affect The Anchoring Effect?

In the actual reinforcement project of planting rebar reinforcement, welding after planting reinforcement is a very common phenomenon. In fact, in GB50367-2013 "Code for Design of Reinforcement of Concrete Structures", the welding of planting reinforcement has been clearly stipulated:

| Rebar diameter d(mm) | Drilling diameter design value D(mm) |

| 12 | 15 |

| 14 | 18 |

| 16 | 20 |

| 18 | 22 |

| 20 | 25 |

| 22 | 28 |

| 25 | 32 |

| 28 | 35 |

| 32 | 40 |

It can be seen from the national standard that, in principle, it is not recommended to perform high-temperature welding after rebar planting. Then, after high-temperature welding, what effect will it have on the rebar planting?

Influence of high temperature welding on planting bars

The high temperature generated by welding will cause the rebar to slip, resulting in a loss of strength. According to a large number of tests, it can be proved that the slippage of planting bars is related to the following factors:

1. Anchorage depth: An increase in anchorage depth can reduce the final slippage of the rebar;

2. Welding position: The closer the welding position is to the colloid position, the greater the slippage of the planting bars;

3. Rebar diameter: The larger the diameter of the rebar, the smaller the slippage of the rebar under high temperature welding.

How much influence does it have on the effect of planting bars after welding? A professional organization has done a set of comparative experiments:

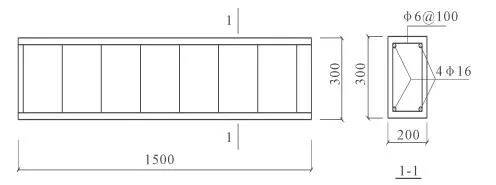

The pull-out test of the planted bars affected by the welding temperature was carried out on reinforced concrete beams. There are 3 test beams and reinforcement, the concrete design strength is C30, and the measured average compressive strength is 38.5N/mm². The diameters of the implanted steel bars Φ12 and Φ16 are 18mm and 22mm respectively. Test results of steel bar material: Φ12 steel bar yield strength 401N/mm², ultimate strength 574.7N/mm² elongation 24.4%; Φ16 steel bar yield strength 385N/mm² ultimate strength 548.7/mm² elongation ratio 22.3%. The design parameters of the pull-out test include the anchorage length (7D, 10D and 15D) and the welding position (the distance from the welding point to the concrete surface adhesive layer is 0mm, 100mm and 200mm).

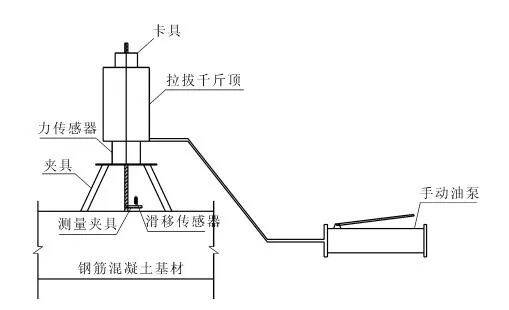

In the experiment, the hydraulic jack was used to apply the pulling force to the implanted steel bar, and the ZDY-300kN cylinder sensor and the JCQ-301 static load tester were used to measure the pulling force. In the test, the steel bars are loaded in stages. The loading level is 10kN for each stage, and the relative slippage data of the steel bars are measured by the YHD30 dial indicator at this time.

At the initial stage of loading, the tensile force on the steel bar and the displacement of the steel bar root have a linear relationship, and the structural adhesive is in the elastic range at this time. When the load continues to increase, vertical and oblique cracks appear in the concrete around the steel bar, and the cracking form is related to the diameter of the steel bar and the anchoring depth.

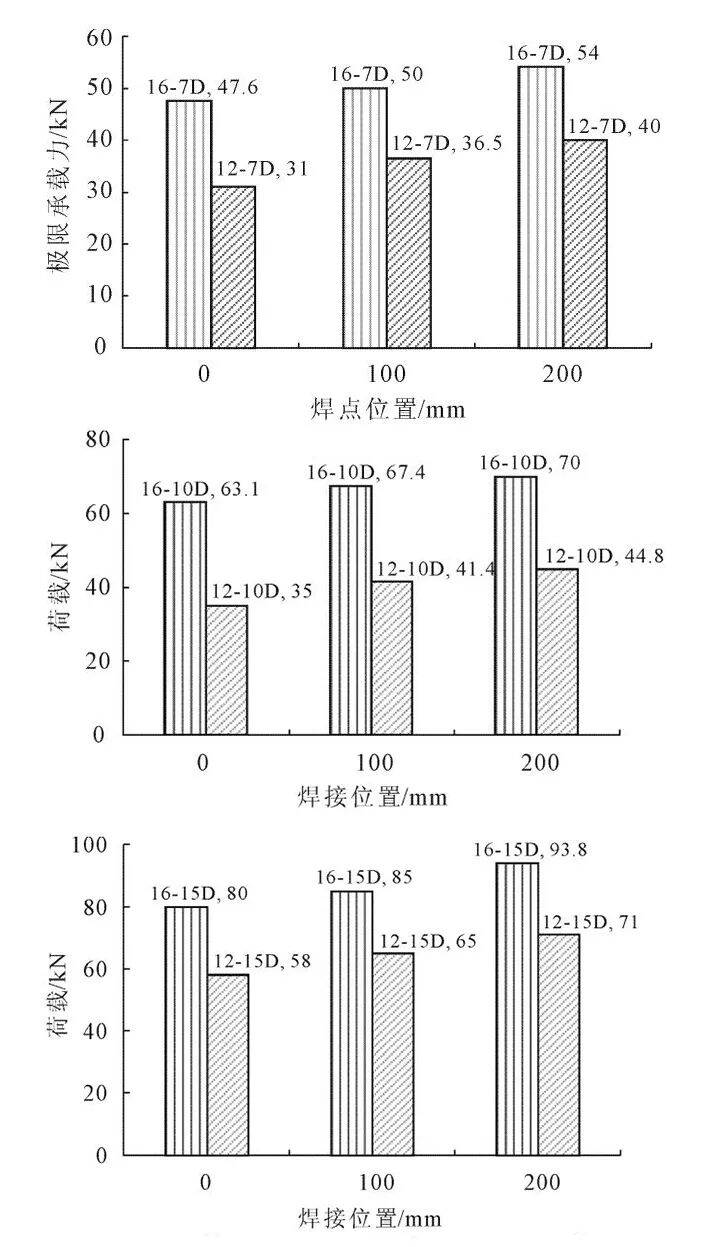

With the increase of the anchorage length, the ultimate bearing capacity of the planted bars increases. The increase of the anchoring depth is beneficial to the improvement of the ultimate bearing capacity of the planting bar. In addition, the determination of the welding position plays a decisive role in the ultimate bearing capacity. The closer the welding position is to the surface of the structural adhesive layer, the more obvious the effect of welding temperature on the structural adhesive, and the lower the ultimate bearing capacity.

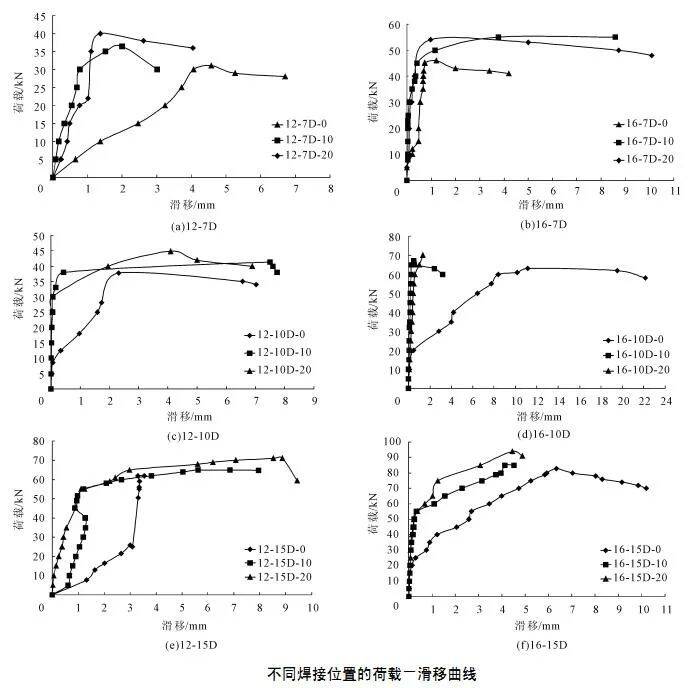

Pull-out force-slip (P-s) curve relationship

The P-s curves of the same kind of steel bar, the same anchorage length, and different welding positions were measured from the test. The following conclusions can be drawn from the analysis of the P-s curve. Before the concrete cracks, the curve is a linear relationship, and the slip of the steel bar is small, showing a large stiffness. At this time, the slope of the straight line is inversely proportional to the distance of the welding position, and the welding position of the steel bar has a significant impact on the pull-out force. When the concrete cracks, the P-s curve of most components turns, and the slope of the curve becomes smaller. After the concrete cracks and before the rebar yields, the curve is still approximately linear, but the slope of the curve is significantly different from that before the cracking.

The planting bar yields and reaches the ultimate load, or the structural adhesive layer is damaged and reaches the ultimate bearing capacity. The slope of the curve decreases sharply, the slip increases sharply, and the slip remains stable or increases within a certain range, and has a good residual adhesive force. When the welding position is 0mm away from the adhesive layer, the adhesive layer is obviously affected by the temperature, the slippage is relatively large, and the ultimate bearing capacity is greatly reduced. When the welding position is 100mm and 200mm, the bearing capacity and slip of the planting bar are not much different, and the drawing force-slip curve is relatively close.

Comparison of the slippage of the planting bar

The slippage of the planted bar is an important indicator of the anchorage performance of the planted bar. Ensuring a small amount of slip is the basic condition for good anchorage, and it is also a sign for judging the failure of the planting bar.

Effect of Anchorage Depth: An increase in anchorage depth reduces the final slip at the same weld location. Under the effect of welding temperature, especially close welding, the increase of anchorage depth cannot reduce the initial slip. Due to the thermal conductivity of the steel bar, the welding temperature has a significant weakening effect on the performance of the upper part of the planting reinforcement adhesive layer, which is more obvious in the planting reinforcement member with a relatively large anchorage depth.

The influence of different welding positions on the P-s curve: the closer the welding position is to the structural adhesive layer, the smaller the initial slope of the P-s curve, that is, the smaller the bond stiffness, the smaller the ultimate load, and the larger the slip. Due to the effect of welding temperature on the upper part of the structural adhesive layer, increasing the anchorage length weakens the effect of welding temperature on the performance of planting bars. The distance from the welding position to the surface of the structural adhesive layer is less than 100mm, and the increase of the anchorage length has no obvious effect on the increase of the slip.

Influence of steel bar diameter: The larger the steel bar diameter is, the lower the slip when the same welding temperature is affected, and the decreasing speed of the ultimate load increases. As the diameter of the steel bar increases, the initial slope of the P-s curve increases, that is, the initial bond stiffness increases with the increase of the diameter of the steel bar.

Through the above analysis, the following main conclusions can be drawn:

(l) Through the pull-out test, three anchoring lengths (7D10D and 15D, D is the diameter of the steel bar) were used for the two steel bars (∅12 and ∅16), at three different welding positions. (The measured distance from the arc drop point is 0mm, 100mm and 200mm respectively) welding. The results show that when the welding position distance is 0mm, the slip is large and the ultimate bearing capacity is greatly affected. With the increase of the anchorage length, the slip of the planting bar gradually decreases; when the welding position is greater than 100 mm, the welding temperature has a significant effect on the initial slip, but has little effect on the ultimate bearing capacity and the total slip. When the welding position distance is 200mm, the effect of welding temperature on the planting bar is not obvious.

(2) Construction suggestion: too small anchoring length directly affects the ultimate bearing capacity and increases the slip of the planting bar. Therefore, the anchoring depth of the planting bar must meet the design requirements. Properly increasing the anchorage depth is beneficial to the improvement of the ultimate bearing capacity of the planting bar. However, in order to prevent the increase of the initial slippage, the distance between the welding position of the rebar and the adhesive layer of the rebar should be as large as 200mm, or appropriate cooling measures should be taken.

How to prevent and improve?

1. Properly increase the anchoring depth. Experiments have shown that an appropriate increase in the anchoring depth can not only improve the ultimate tensile bearing capacity of the planting bar, but also reduce the slippage of the planting bar.

2. Increase the distance from the welding point to the adhesive layer of the reinforcing bar. Increasing the distance from the welding point to the rebar planting adhesive layer directly reduces the influence of high temperature welding on the rebar planting.

3. In the case where the above methods cannot or should not be used, the planting glue that has passed the high temperature welding pull test can be used.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package for anchoring