Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Application of Prestress Technology in Bridge Engineering

1 Application in bending members

(1) The flexural component is the key to bridge engineering, and it is also the difficulty of current bridge construction. In order to effectively improve the construction performance of the flexural components and ensure that the flexural components have ideal bearing capacity and tensile strength, prestressing technology can be used for construction to optimize the overall performance of the flexural components and play an active role in durability. .

(2) Prestressed construction techniques are used in the construction of flexural components of bridge engineering, and attention should be paid to the selection of carbon fiber boards. After ensuring that the carbon fiber board is better combined with the bending member, the pre-stressed tension can be carried out to improve the mechanical properties of the bending member and ensure the strength of the bending member. In the pre-stressed construction of bending members, the use of inferior materials should be avoided.

2 Application in prefabricated slab

(1) Bridge construction has higher and higher requirements for prefabricated slabs. Therefore, pre-stressed technology should be used in the construction of prefabricated slabs. To increase the stability of the precast slab concrete structure and improve the crack resistance of the precast slab, thereby improving the strength and rigidity of the bridge.

(2) The use of prestressing technology in the construction of prefabricated slabs can effectively reduce the cross-section of the bridge, reduce the weight of the bridge and save materials to control costs. At the same time, the use of prestressing technology can improve the fatigue resistance of the prefabricated panels and enhance the strength of the prefabricated panels, thereby prolonging the service life of the bridge and ensuring the construction quality of the bridge.

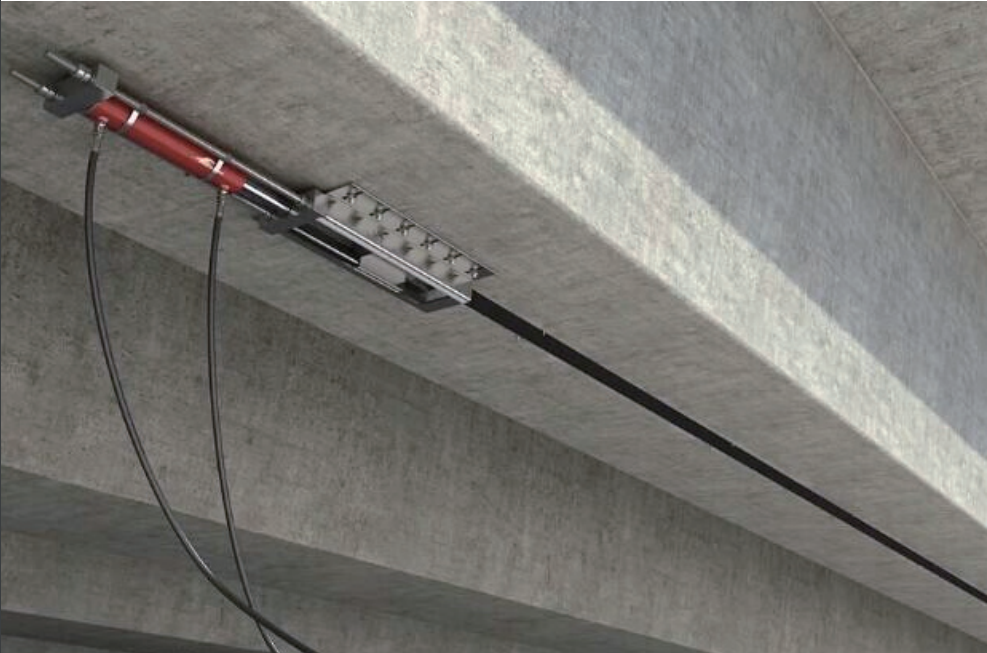

3 Application in bridge reinforcement

Pay attention to bridge reinforcement engineering to further improve or restore the bridge's bearing capacity to meet the needs of traffic development. The application of prestressing technology for bridge reinforcement construction can effectively increase the bridge's bearing capacity and meet the needs of normal bridge operation

4 Application in concrete box girder

Before the construction of prestress technology, technicians are required to make various preparations and inspect the proportion of concrete. During the construction of the prestress technology, detailed construction should be carried out in strict accordance with the design content of the drawings, and the stranding and tensioning of the steel strands should be done to ensure the construction quality of the bridge concrete box girder.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Prestressed carbon fiber reinforced polymer(CFRP) strip for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Prestressed carbon fiber reinforced polymer(CFRP) laminate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.