Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fiber Reinforced Various Cross-section Methods

When carbon fiber cloth is used in bridge reinforcement, it can reinforce the bearing capacity of the normal section of the member that bears bending moment and shear; strengthen the bearing capacity of the oblique section; strengthen the shear of the section. In addition, carbon fiber cloth can also be used to strengthen the pressure member.

(1) Strengthening the front section bearing capacity

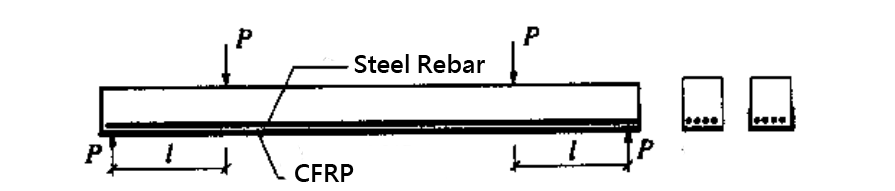

When carbon fiber cloth is used to reinforce the front section bearing capacity of the bending member, the pasting method as shown in the figure is generally adopted.

Paste one or several layers of carbon fiber cloth on the bottom of the beam, and its cross-section can be made as shown in the figure. If possible, the carbon fiber cloth should be pasted into the U-shaped cross-section in the picture, and the bearing capacity of the front cross-section of this cross-section can be increased even more. The number of pasted layers can be calculated quantitatively with reference to the calculation method of the front section bearing capacity in the "Design Principles of Concrete Structures". In the calculation, the assumption of a flat section is still used, and the reduction of the strength of carbon fiber cloth is appropriately considered (the strength of general carbon fiber cannot be fully utilized), and it is recommended to take 60% of its strength.

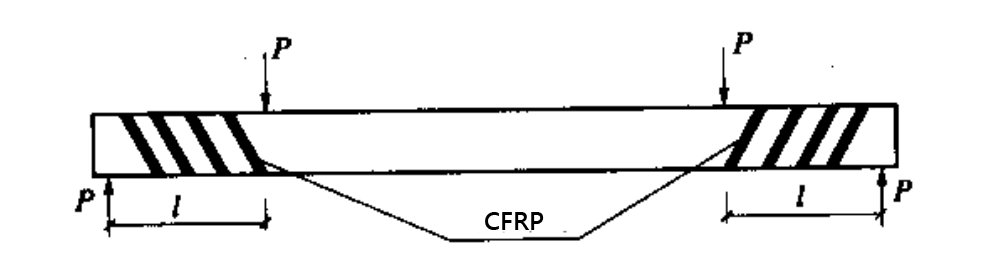

(2) Strengthening of the bending resistance of the oblique section and the shearing of the section

When carbon fiber cloth is used to strengthen the flexural resistance of the oblique section or to improve the shear resistance of the section, the pasting method as shown in the figure can generally be used. Cut the carbon fiber cloth into strips and paste it on the side of the beam. The paste direction should be consistent with the main tensile stress trace in the beam. In this way, the carbon fiber cloth can give full play to its tensile performance, prevent concrete from cracking, and thus can also improve the shear resistance of the beam. When calculating, you can still consider the role of carbon fiber cloth in the consideration of the bending and shear resistance of bent steel bars in the "Design Principles of Concrete Structures", and then determine the amount of carbon fiber cloth.

(3) Reinforcement of compression members

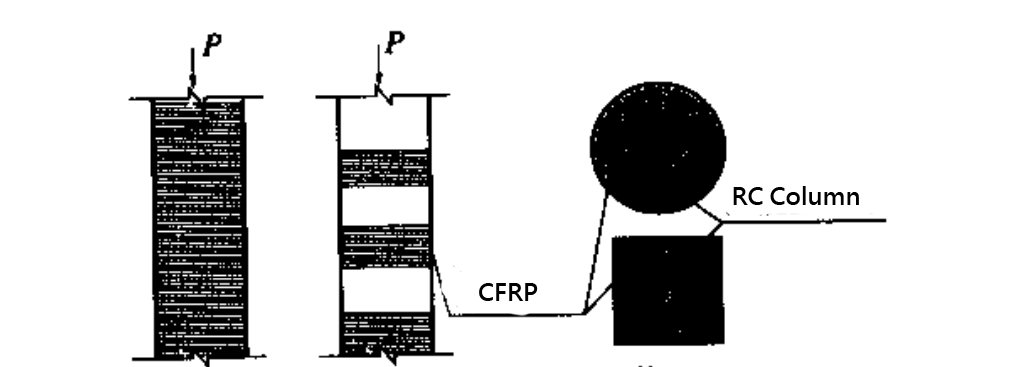

When carbon fiber is used to reinforce a compressed concrete column, the pasting method as shown in the figure can generally be used.

In the reinforced compressed concrete members, the role of carbon fiber is similar to the role of stirrups in concrete columns. Therefore, when calculating, you can still refer to the treatment method of stirrups in the "Concrete Structure Design Principles" to quantify the role of carbon fiber cloth to determine the number of layers to be pasted. In addition, the column can be completely wrapped with carbon fiber or partially wrapped. Initial studies have shown that partial wrapping may be more advantageous, as shown in the elevation view of the figure.

The concrete column reinforced with carbon fiber cloth can not only increase the bearing capacity, but also increase the ductility of the concrete column. Therefore, it is more advantageous to use it when strengthening bridge piers in areas with frequent seismic activities.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.