Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

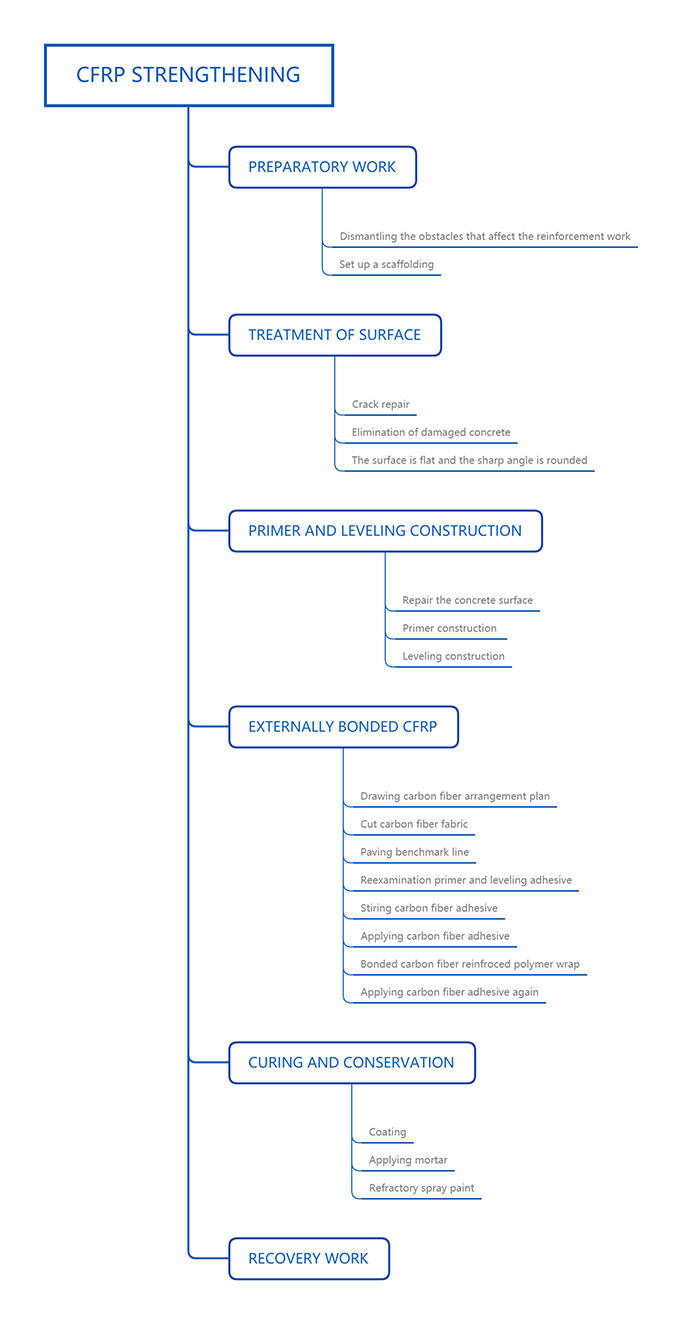

6 construction details determine the effect of carbon fiber reinforcement

Everyone is very clear about the construction process of carbon fiber sheet reinforcement. But using the same construction process, why is the reinforcement effect of your project not good? Today, I will talk about these 6 points that should be paid attention to in the construction of carbon fiber sheet reinforcement. The following description is based on: GB50550-2010 "Code for Acceptance of Construction Quality of Building Structure Reinforcement Engineering".

For the repair of concrete base material, the edges and corners of the structural section should be polished to a rounded corner with a radius of no more than 25 mm to keep the concrete surface clean and dry. The moisture content of the concrete surface layer shall not be heavy rain 6%, and the moisture content tester shall be used for testing during the construction period.

Brush glue for carbon fiber sheet, if it is equipped with a primer, you must brush the primer first, so that the finger is dry before the surface glue operation. If the primer is dry, you must wait 12 hours before sticking the carbon fiber sheet. For the primer operation, the primer must not be removed without authorization, and the primer must not be added with a thinner to change its viscosity. Except for primer-free dipping glue.

When the carbon fiber sheet is pasted, the surface must be fully flattened without wrinkles, and the layer must be evenly compacted without air bubbles. When multi-layer pasting, the next layer of work must be performed when the carbon fiber sheet of this layer reaches finger dryness. The delay time exceeds 1 hour, and the work will be performed after waiting for 12 hours.

After the construction of the carbon fiber sheet, let it stand still for 7 days. After it is completely fixed, check whether there is any hollowing phenomenon. The area of a single hollow drum shall not rain 10000 square millimeters, and the injection method is allowed to fill it for repair. If the area of a single hollow drum is greater than 10,000 square millimeters, the carbon fiber sheet should be cut and re-attached, and the joint should be no less than 200 mm in the direction of the hand. If the number of sticking layers exceeds 3 layers, the lap joint shall not be less than 300 mm, and the lap joint in the non-stressed direction shall not be less than 100 mm.

There is a very important point here, that is, the glue layer. Some customers use a small amount of glue in order to save costs. This is wrong. The carbon fiber sheet glue layer should be controlled at 1.5 mm and floated by 0.5 mm.

Qualified indicators for on-site inspection of the positive tensile bond strength of reinforcement materials and concrete:

| Test items | Measured concrete strength grade of original component | Test qualification index | Detection method | |

| Tensile bonding strength and its failure mode | C15-C20 | ≥1.5MPA | And cohesive failure of concrete | GB50550 |

| ≥C45 | ≥2.5MPA | |||

Note: If the test result is between C20~C45, the corresponding intensity level is determined by interpolation.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.