Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

A Table Can Understand The Causes Of Concrete Cracks

Can you analyze the cause of the crack formation from this picture? If not, you can take a look at the following table, and HORSE Construction will summarize it for you. How to analyze the cause of crack formation through the appearance characteristics of concrete cracks.

| Causes of cracks | Characteristics of cracks | |

| 1. Concrete materials | 1. Cement setting (time) is abnormal | Irregular cracks appear in the initial stage of concrete setting of larger area |

| 2. Abnormal expansion of cement | Radial network crack | |

| 3. Floating slurry and sinking when concrete is set | One or two hours after the concrete is poured, it occurs intermittently on the steel bar and at the junction of the wall and the floor. | |

| 4. Mud in aggregate | Irregular net-like dry cracks appear on the surface of the concrete | |

| 5. Heat of hydration of cement | 1 to 2 weeks after the mass concrete is poured, straight cracks at regular intervals appear at regular intervals, some on the surface and some through | |

| 6. Hardening and drying shrinkage of concrete | Two or three months after pouring, it gradually appeared and developed. Oblique cracks appeared in the windows and the end corners of beams and columns. | |

| 2. Construction | 1. The mixing time is too long | Reticulated cracks and irregular long and short cracks appear across the board |

2. Increase the amount of water and cement when pumping | Easy to appear net-like and irregular long and short cracks | |

3. Reinforcement stepped on chaotically, and the steel protective layer was thinned | Occurs around the concrete ribs and along the surface of the reinforcement and piping | |

4. Pouring speed is too fast | After pouring for 1 to 2 hours, cracks appeared on the steel bar, at the junction of the wall and the slab, and the beam and the column. | |

5. Pouring is uneven and not dense | Easy to become the starting point of various cracks | |

6. the template bulges | Parallel to the moving direction of the template, some cracks appear | |

7. Poor handling of stubble | Cold stubble cracks appear at the stubble | |

8. Vibrate or load before hardening | Cracks in the stressed state appear after hardening | |

9. Insufficient initial maintenance | Shortly after pouring the letter, irregular short cracks and fine cracks appeared on the surface. After demoulding, the concrete surface appears white, hollow, etc. | |

| 10. Formwork pillars sink | Cracks appear on the ends of beams and floor slabs and below the middle part | |

| 3. Influence of climate and environmental factors | 1. Temperature, temperature change | Similar to shrinkage cracks, the existing cracks change with the environmental temperature and temperature changes |

| 2. The temperature and humidity difference between the two sides of the concrete member | On the side of low temperature or low humidity, it is easy to occur at the corners | |

3. Multiple freeze-thaw cycles | On the side of low temperature or low humidity, it is easy to occur at the corners | |

4. The fire surface is heated | Turtle head cracks appear on the entire surface | |

5. Corrosion and expansion of steel bars, large cracks, even spalling, and rusty water flow along the steel bars, etc. | Large cracks appear along the steel bars, even peeling off, rusty water, etc. | |

| 6. Corroded by acid and salt | Or the surface of the concrete is corroded, or expansive substances are produced, and it collapses | |

| 4. Structure and external influence | 1. Overload | Vertical cracks appear on the tension side of the beam and the floor |

| 2. Earthquakes and accumulated loads | 45° oblique cracks occur in columns, beams, walls, etc. | |

| 3. Insufficient amount of steel bars in section | Vertical cracks appear on the component under tension | |

| 4. Uneven subsidence of the foundation of the structure | 45° big crack occurred | |

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength crack sealing repairing adhesive for the fracture surface of concrete crack

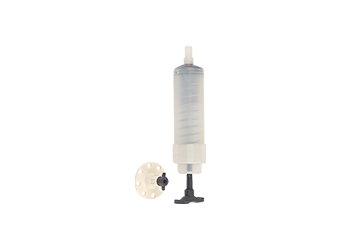

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack