Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Main Points Of Reinforcement And Repair Of Old Buildings

1 Project Overview

The main body of a building in Zhongshan Old Town, Guangdong is a 5-story mixed structure with a height of 3m and a brick wall bearing capacity. The building area is 996 square meters. Due to disrepair for a long time, the whole brick joint mortar was seriously powdered, the roof and walls leaked in many places, the concrete lock beams of some corridors burst, and the steel bars were corroded. There are large trees growing on the wall, a large number of tree roots grow into the brick joints, the masonry is seriously damaged and deformed, and the overall rigidity is insufficient. The house safety appraisal shows that the building is close to the building service life specified in the design code, the building materials are seriously degraded, and the house is in a dangerous state. It should be stopped immediately, and on-site maintenance should be done. It is recommended to carry out reinforcement repair or dismantling immediately.

After reinforcement

2 Reinforcement and repair methods and construction technical points of key parts

2.1 Adopt carbon fiber cloth to strengthen the floor slab

The building is a masonry mixed structure, in which the bathroom, kitchen, and balcony are cast-in-place structural slabs, and the others are precast concrete slabs. The key reinforcement parts of this project are cast-in-situ structural slabs and precast concrete slabs. In order to ensure structural safety and reinforcement quality, it is particularly important to reinforce the precast concrete slabs at key locations. In addition, the reinforced area of the prefabricated slab is partially supported to prevent excessive vibration.

① Use enclosed paste, U-shaped paste or side paste to strengthen the component under shear, and the fiber direction should be perpendicular to the component axis.

②The lap length of the carbon fiber cloth along the fiber direction should not be less than 50mm. When multiple or multiple layers of carbon fiber cloth are used for reinforcement, the overlapping positions of each or each layer of carbon fiber cloth are staggered.

③Cut the carbon fiber cloth according to the size required by the design; prepare the impregnating resin according to the process regulations provided by the product manufacturer, and apply it evenly on the sticking part. Lightly press the carbon fiber cloth on the position to be pasted by hand, and use a special roller to roll in the fiber direction several times to squeeze out the bubbles, so that the impregnating resin can fully penetrate the carbon fiber cloth, and the carbon fiber cloth shall not be damaged during rolling. For multi-layer pasting, the above steps should be repeated, and the next layer should be pasted as soon as possible after the impregnating resin on the fiber surface is dry. The impregnating resin should be evenly spread on the surface of the last layer of carbon fiber cloth, and mung bean sand should be glued on the surface.

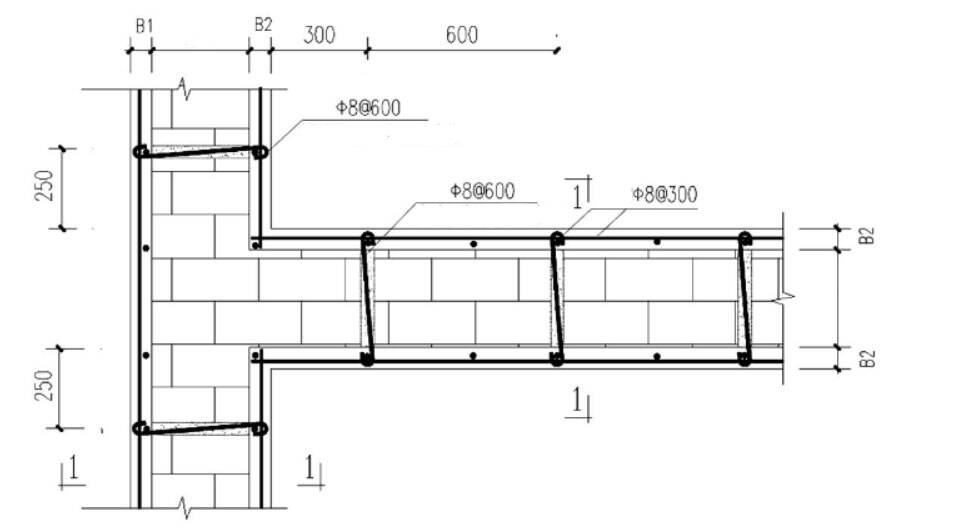

2.2 Reinforce the original load-bearing wall using double-sided steel mesh plywood wall reinforcement

The main load-bearing component of the structure is the wall, and the requirements for wall reinforcement are also very strict. As the building is surrounded by old buildings with a long history, the working face of wall reinforcement construction is very narrow and operation is difficult. In order to ensure structural safety, the quality of wall reinforcement at key locations is extremely important. The wall shall be constructed layer by layer by layer by layer and section by section using high-strength polymer cement mortar with reinforced mesh on both sides.

Sum up

The building has been used for more than 40 years. The concrete lock beams of some corridors burst, the steel bars were corroded, most of the concrete precast slabs on the floor deformed, and obvious cracks appeared in the handover positions, and the overall rigidity was insufficient. The bearing capacity of the walls and lock beams no longer meet the requirements of use, so the reinforcement construction of the walls is the top priority of this reinforcement and repair project. After the project is reinforced and repaired, the service life of the building can be extended by 30 years.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Two-component modified epoxy resin adhesive, applied to chemical planting reinforcing bar and anchor bolt anchoring

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete