Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Application of Carbon Fiber in Reinforcement of Multi-layer Concrete Frame Column

Projects

A certain multi-layer reinforced concrete frame warehouse project, the column net size is 6m×6m, the column height is 4.5m, the cross-section is 600mm×600mm, and the four corners of the column are designed with rounded corners of R: 50mm. The multi-layer frame was poured with commercial concrete. When the main structure was constructed to a 5-story floor, it was found that the concrete strength of the 3-story partial frame column was lower than the design value. Subsequently, the on-site rebound strength test was carried out on the concrete of each column of the entire layer. The rebound results showed that there are 3 columns of concrete whose strength grade is only around C10 (33.33% of the original design strength). There are 4 columns and the concrete strength grade is only around c18 (60% of the original design strength).

Determination of reinforcement plan

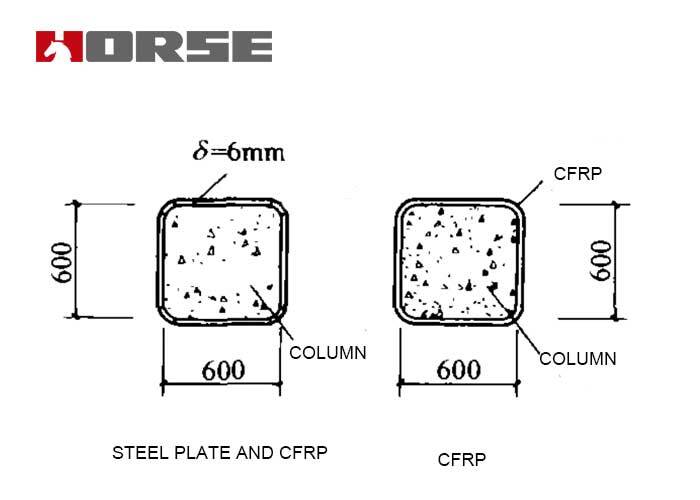

The column with the concrete strength level of C18 is wrapped with carbon fiber cloth to increase the compressive strength and meet the design requirements.

Steel plate inside and carbon fiber cloth outside

For the column with concrete strength grade only about C10, the internally bonded thin steel plate (thin steel plate is 500mm wide and 6mm thick) and the outer carbon fiber cloth is wrapped to improve the compressive strength of the concrete column, meet the seismic requirements, and achieve the design strength of the column .

Reinforcement construction of concrete column with carbon fiber cloth

Column concrete surface inspection and laying line

Column concrete surface repair and crack repair

Column concrete surface pretreatment

Preparation of adhesive and preparation of carbon fiber materials

Coating adhesive and sticking carbon fiber cloth

Curing of adhesive

Acceptance

The effect of frame column reinforcement

(1) After reinforcement with carbon fiber, the traces of the reinforcement are basically not visible, and the cross-sectional geometric dimensions are only 2~7mm larger than the original design.

(2) There is no need to consider the maintenance during the future use after one time of reinforcement. Although the cost of carbon fiber reinforcement is higher than that of bonded steel reinforcement, its construction speed is fast (this time it only took 2 days from the preparation to the completion of the reinforcement), which can save construction costs and has long-term comprehensive benefits.

(3) Four observations within 2 years after the completion of the reinforcement show that the bottom of the reinforcement column and the upper measurement points have not changed, and the fixed sound frequency of the hammer tapping sound on the carbon fiber reinforcement part has not changed.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.