Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Case Study | Reinforced Method of Reinforced Concrete Column

Due to the update of specifications and the emergence of layered structures, some buildings that cannot meet the requirements of use need to be reinforced to ensure their safety. As an important component in the structure, the reinforcement of columns is particularly important. The article mainly introduces several methods of column reinforcement, including increasing section method, externally pasted steel reinforcement method, pasting carbon fiber reinforced composite material reinforcement method and pasting copper plate reinforcement method. And focus on the analysis of the design principles of various reinforcement methods, which can be used as a reference for reinforcement engineering practice

Enlarged section reinforcement method

The increased section reinforcement method uses concrete materials to increase the cross-sectional area of the original member, thereby improving the load-bearing capacity and rigidity of the original member. As one of the traditional reinforcement methods, the enlarged cross-section reinforcement method has a very mature technology, which is characterized by simple construction and is suitable for components where the cross-sectional size of the concrete column is too small or the axial compression ratio needs to be significantly improved. When designing, it is necessary to add longitudinal steel bars on several or all sides of the column section according to the specific situation and pour concrete to strengthen the column. During the reinforcement, the new and old steel bars should be welded to do a good job in combining the new and old concrete.

External bonding steel reinforcement method

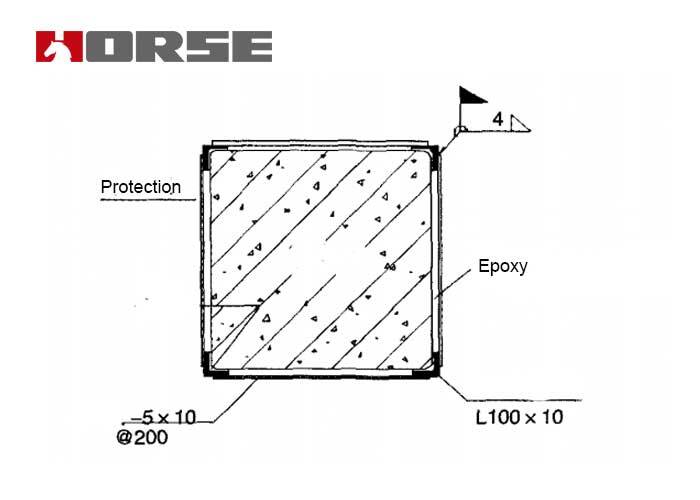

The external bonding steel reinforcement method is a reinforcement method in which section steel (angle steel, flat steel plate, etc.) is wrapped on the surface of the member, and the frame is formed by the affixed material, and the structural adhesive is bonded to the original member to achieve a common work effect. All or part of the original components are replaced by the outsourcing steel frame, so as to achieve the purpose of the outsourcing steel frame and the original components under the same force. The construction process of the rectangular column is that the four corners of the column are wrapped with angle steel, and the columns are separated by a certain distance in the transverse direction and welded with plaques.

The advantage of the externally bonded steel reinforcement method is that the section size of the member is not significantly increased, and it has a good effect on the improvement of the bearing capacity of the member. The outer steel has the function of constraining the concrete of the component, which improves the bearing capacity and ductility of the original column. The external bonding steel reinforcement method also has the characteristics of simple construction and short construction period. However, the disadvantage of the outer steel method is that it costs more materials and the construction is more complicated, especially for the outer steel reinforcement, anchoring and bonding construction in the frame node area.

Bonding carbon fiber reinforced polymer(CFRP) material reinforcement method

The technology of sticking carbon fiber structure reinforcement is to use structural adhesive to stick the fiber composite material on the surface of the component, mostly on the surface of the main tension area of the component, to improve the bending, shear and concrete compressive strength of the section.

Because fiber composite materials and concrete are two materials with different properties. The difficulty of fiber composite material reinforcement method is how to ensure that the reinforced fiber material can coordinate the force with the original member. The study of the interface between the two is the difficulty of the reinforcement method. In addition, the high strength and low elastic modulus of fiber materials are also a factor that prevents them from exerting their maximum reinforcement effect. To make the fiber-bonded composite reinforcement method exert its reinforcement effect, it is necessary to ensure that the reinforcement material and the original member have sufficient anchoring measures.

Paste steel plate reinforcement method

The sticking steel plate reinforcement method is a new reinforcement technology for building structural engineering, which is similar to the outer steel reinforcement method. The difference between the two is that the steel-bonded reinforcement mainly uses a thin steel plate to be pasted on the main bearing surface of the member to improve the bearing capacity of the section. For simply supported beams or plates, the steel plate should be pasted on the bottom surface of the member. When the bearing capacity of the reinforcement in the negative bending moment zone is insufficient, the steel plate should be attached to the top of the component. In addition, the stick-steel reinforcement of the continuous component is affected by obstacles such as wall columns, and corresponding measures need to be taken. Compared with other reinforcement methods, the pasting steel plate method has many advantages, which are shown in: it does not change the shape of the concrete component, does not affect the building space, and the construction is convenient and quick.

Case Study

Addition and reinforcement of section B of the main teaching building of a school. The original teaching building has 4 floors. Due to functional requirements, 2 floors of steel structures need to be added to the top of the building. That is, the original structure is increased by a two-story steel frame structure, the floor is a profiled steel plate composite floor, and the roof is a light steel roof. The safety level of the building structure is Class II, and the seismic protection class of the building is Class C. Structural seismic grade: concrete frame is grade three, steel frame is grade four. The seismic fortification intensity is 7 degrees (0.1g), and the designed earthquake group is the first group. Construction site category: Class II.

Due to the addition of two more layers of steel structure, the axial compression ratio of some columns does not meet the seismic requirements, and the columns need to be reinforced. There are many ways to reinforce columns. In the four reinforcement methods introduced in this article, each method can be used in principle. The appropriate reinforcement method should be selected according to the specific situation. This project requires that the use space of the original structure is not reduced as much as possible and the construction period is relatively short, so the method of increasing the column section cannot be used for reinforcement. It is good to stick carbon fiber reinforcement, but because after adding 2 layers of steel structure, according to calculation, it is necessary to stick more than 3 layers of carbon fiber, which is relatively expensive, so we consider using outer steel for reinforcement. In addition to this reinforcement method, the outer steel and the reinforced old concrete column can work together to improve the bearing capacity of the column. The outer steel column forms an overall tight band, which partially restrains the original concrete. Increasing the compressive strength of the original concrete can also increase the bearing capacity of the column. The reinforcement diagram is shown in the figure below.

In conclusion

This article introduces the respective characteristics of the enlarged section method, the externally bonded steel reinforcement method, the bonded carbon fiber reinforced composite material reinforcement method, and the bonded steel plate reinforcement method. In the teaching building's extra-storey reinforcement and renovation project, the design should consider the influence of the extra-storey part on the original structure and select a reasonable reinforcement method for reinforcement after calculation and analysis in combination with the current code. It focuses on comparing the pros and cons of several methods to provide reference for future actual engineering reinforcement.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete