Summary: The global carbon fiber structural reinforcement market was approximately US$1.8 billion in 2025, with a CAGR of 12.0% from 2026 to 2031, and is expected to reach US$3.316 billion by 2031. The Asia-Pacific region (with China at its core) is experiencing the fastest growth, while North America holds the largest market share.

The global carbon fiber structural reinforcement market was approximately US$1.8 billion in 2025, with a CAGR of 12.0% from 2026 to 2031, and is expected to reach US$3.316 billion by 2031. The Asia-Pacific region (with China at its core) is experiencing the fastest growth, while North America holds the largest market share. The industry is driven by advancements in five key dimensions: technology, construction, applications, sustainability, and standards.

I. Market Size and Regional Landscape

1)Key Data (2025-2031)

Global market size in 2025: Approximately US$1.8 billion (approximately 12.96 billion RMB).

Market size in 2031: Expected to reach US$3.316 billion, with a CAGR of 12.0%.

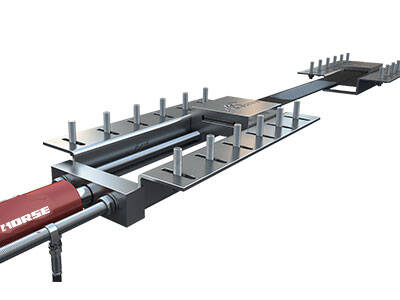

Product Structure: Carbon fiber fabric accounts for the largest share (approximately 40%), while carbon fiber plates and rebars are experiencing rapid growth, adapting to different reinforcement scenarios.

2)Regional Distribution

North America: Accounts for 36.55% in 2024, driven by aging infrastructure upgrades and strict regulations, with the United States as the core market.

Asia Pacific: Fastest growth rate (CAGR 11.57%), driven by urbanization and urban renewal in countries such as China and India, with China accounting for approximately 40% of the global market.

Europe: Stable growth, focusing on historical building preservation and seismic reinforcement, with a high proportion of green certified projects.

Middle East & Africa: Accelerated infrastructure investment, with Chinese companies' exports growing at an annual rate of over 20%, becoming a new growth point.

II. Core Development Trends

1) Materials Technology: High Performance + Low Cost + Intelligent Integration

High modulus and large tow fibers in parallel: T700-grade carbon fiber is accelerating its engineering application, and mass production of 24K large tow fibers is driving down costs.

Intelligent materials implementation: Self-sensing carbon fiber fabric (integrated with optical fibers/conductive polymers) achieves a monitoring accuracy of 98%, suitable for bridge and skyscraper health monitoring, with a market potential of approximately 8 billion RMB.

2) Application Scenarios: Diversified Expansion and High-End Breakthroughs

Structural Type Extension: From concrete to masonry, steel, and timber structures, covering factories, tunnels, subways, and historical buildings. The lightweight advantage is driving an increase in the proportion of historical building reinforcement projects.

Penetration into High-Risk Scenarios: In corrosive/heavy-load environments such as offshore wind power, offshore platforms, and chemical facilities, carbon fiber's excellent corrosion resistance significantly reduces maintenance costs by 40%.

Globalization Expansion: Chinese companies, leveraging their cost and technological advantages, are exporting to Southeast Asia, the Middle East, and Africa, with an annual growth rate exceeding 20%.

3)Construction Management: Intelligent, Modular, and Digitally Integrated

Widespread adoption of intelligent construction: AI design shortens cycles by 40%, and robotic application/spraying + drone inspection shortens construction time by 60%; modular prefabrication improves efficiency by 3 times, suitable for urban renewal projects.

Digital management and control: BIM + IoT realize construction monitoring and quality traceability; ultrasonic and infrared thermal imaging are used routinely to ensure bonding quality and reduce maintenance costs.

4)Standards and Ecology: Collaborative Integration for Improved Efficiency

International Standards Convergence: International organizations lead the way in establishing unified standards, promoting cross-border mutual recognition, and reducing trade barriers.