Segmental Bridge Construction

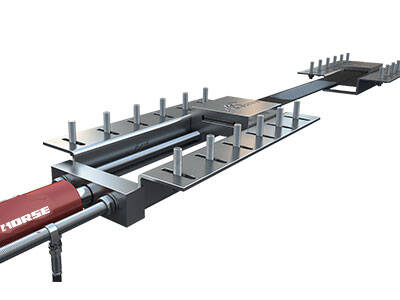

HM-120SC

Select language

HM-120SC

The Singapore Bridge Project is a key project for upgrading the local transportation network, constructed using segmental prefabrication and assembly technology, with the core being a multi span continuous box girder structure.

The Singapore Bridge Project is a key project for upgrading the local transportation network, constructed using segmental prefabrication and assembly technology, with the core being a multi span continuous box girder structure.

In response to project requirements, we provide customized two-component epoxy segmental adhesive HM-120SC, with the following core advantages:

Excellent mechanical properties: key indicators such as tensile strength and steel to concrete tensile bond strength meet the A-level adhesive standard, and the elastic modulus matches C50 concrete, effectively coordinating structural deformation and transmitting loads.

Outstanding environmental tolerance: Through specialized wet heat aging and heat aging tests, a dense sealing layer is formed after curing, with excellent moisture and anti-seepage performance, suitable for Singapore's climate environment.

Convenient and efficient construction: The thixotropy index meets the standard, and it is not easy to flow after painting. It can be applied on damp surfaces, and the curing speed is controllable without affecting the subsequent prestressing and tensioning process, helping to improve assembly efficiency.

Safe, environmentally friendly, and reliable: non-toxic and odorless, with low heat release during the curing process, avoiding the impact of high temperature on the performance of precast concrete for box girders, and meeting the environmental requirements of Singapore infrastructure projects throughout the process.

The adaptability and reliability of segmental glue in overseas high standard bridge engineering provide a high-quality bonding solution for the construction of segmental prefabricated and assembled bridges in Southeast Asia.

Website Map | Corporate | Contact | Privacy