Bridge Reinforcement

Carbon Fiber Sheet

The safety and reliability of bridges have been improved with carbon fiber sheet, the maintenance period of bridges has also been extended, the operational efficiency of bridges has been improved, and social and economic benefits have been improved.

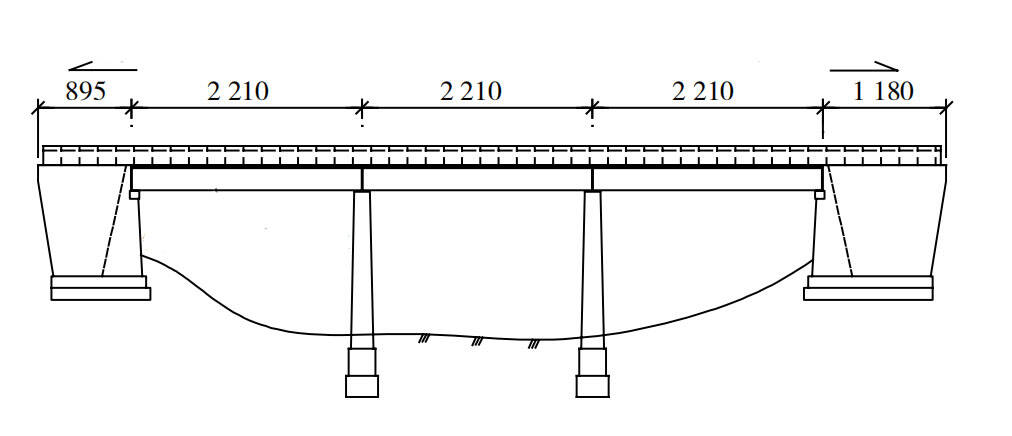

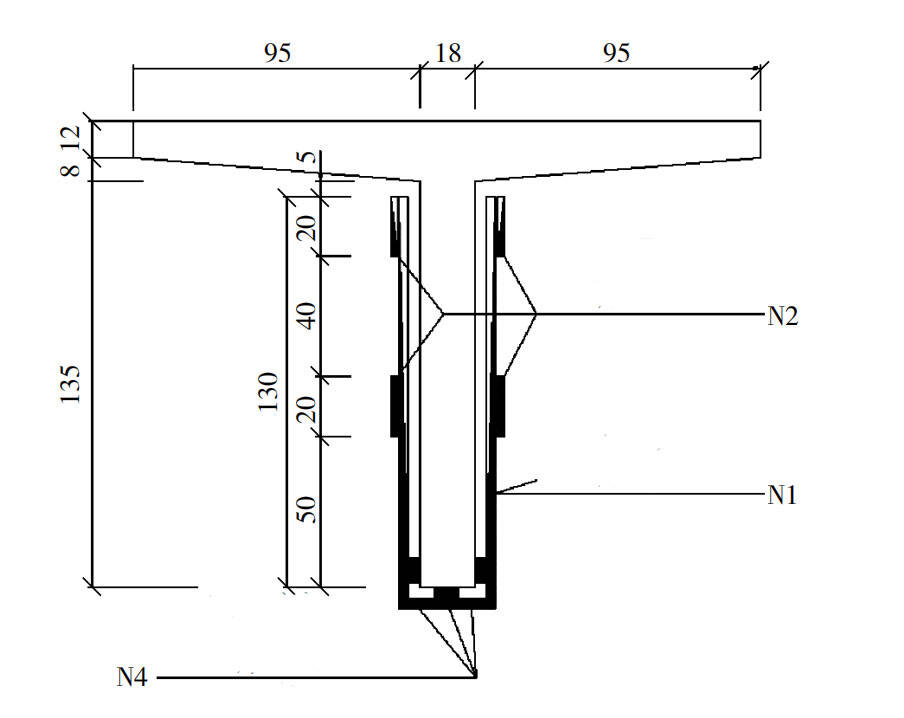

The old and new parts of the superstructure of the bridge are independent of each other. Judging from the specifications of the bridge body, the upper structure is a T-shaped bridge of reinforced concrete, with a length of 3m and a width of 22.5m. The entire span is composed of 5 pieces of T-shaped beams, and the supports are made of plate rubber, a total of 10. The beam height is 1.55m, there are wings on both sides, and the width is 2.1m. The paving material of the bridge deck is cement concrete, with a width of 9.3m, of which the sidewalk is 2.2m and the motor vehicle lane is 7.1m. The lower structure of the bridge is based on the old abutment, which integrates the abutment with the gravity pier and abutment, and expands the foundation of the bridge body. The load design of the bridge is: car – class 20, hang – 100. The layout of the bridge elevation is shown in Figure 1.

Major diseases in engineering

It was built in 1991 and has been in operation for more than 20 years. Under the influence of factors such as long-term high load, overloading of vehicles and shrinkage of concrete itself, the bridge body has experienced local cracks. There are vertical cracks on the web surface of the main girder (T-shaped beam) of the bridge, mainly distributed in the third span. The cracks do not penetrate the web, and a few cracks exceed the limit requirements, and no cracks are found at the bottom and ends of the beams.

Reinforcement method

(1) In view of the insufficient bearing capacity of the T-shaped beams in the new design load, carbon fiber sheets are used to reinforce the cracks of all the T-shaped beams of the original bridge after sealing treatment. The bottom plate of the T-shaped beam is pasted in a single longitudinal strip of carbon fiber sheet, the width of a single strip is 5 cm, and 3 strips are pasted; the lower edge of the web of the T-shaped beam is pasted with a single longitudinal strip of carbon fiber sheet, one on each side, and the width of a single strip is 10 cm.

(2) The web is covered with carbon fiber sheet along the longitudinal direction of the T-beam.

(3) After the construction is completed, apply colloid on the outer surface of the carbon fiber cloth for protection.

After the carbon fiber sheet was used to reinforce the construction, the owner commissioned a third party to carry out dynamic and static load tests, and the test results met the design requirements. At present, the project has been put into operation for 10 years. Through the return visit, it is known that there is no phenomenon of falling off or cracking, which meets the operation requirements. Judging from the implementation effect of reinforcement and maintenance of the project, the project was very successful. The safety and reliability of bridges have been improved, the maintenance period of bridges has also been extended, the operational efficiency of bridges has been improved, and social and economic benefits have been improved.