Old Wharf

Repair And Reinforcement

There are usually two methods for pasting carbon fiber cloth on concrete square piles, namely, pasting along the longitudinal direction of the pile foundation and in the circumferential direction.

Common Damage Defects of Concrete Square Pile in Old High Pile Wharf

Pile body cracking (longitudinal, transverse or circumferential cracks), local concrete damage (peeling, spalling), exposed tendon corrosion, broken piles, etc., often lead to a decrease in the bearing capacity and durability of the pile foundation. If it is not detected and evaluated in time and effective repair and reinforcement measures are taken, the existing damage defects will be aggravated and deteriorated, the potential accident risk will increase, and the structural safety and use function of the wharf will be seriously affected.

Pile top concrete damage

Pile body cracking, local concrete damage

Concrete spalling of pile body, exposed tendons and corrosion

broken pile

Paste CFRP for repair and reinforcement

The repair and reinforcement of pasted CFRP has the characteristics of simple construction, high construction efficiency, no need for large equipment and formwork, no increase in structural size and weight, good corrosion resistance and durability, and convenient molding. It has significant advantages in construction period and construction conditions. It has been widely used in port and wharf repair and reinforcement projects. There are usually two methods for pasting CFRP on concrete square piles, namely, pasting along the longitudinal direction of the pile foundation and in the circumferential direction. The CFRP pasted in the circumferential direction of the pile foundation is equivalent to additional stirrups, which can restrain the lateral deformation of the pile foundation, inhibit concrete spalling, crack propagation and longitudinal reinforcement buckling, thereby improving the ductility and shear resistance of the pile foundation.

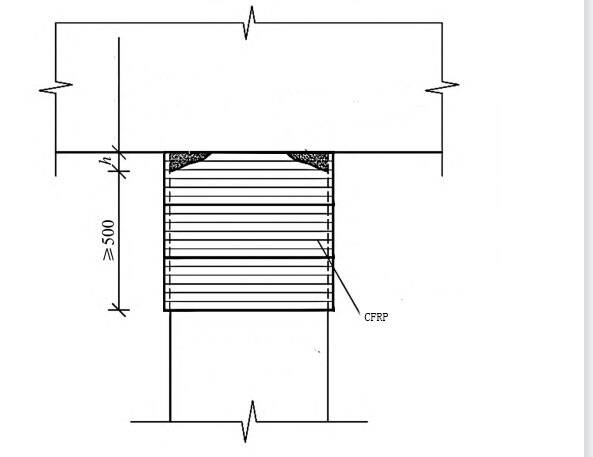

Pile top concrete damage repair with CFRP

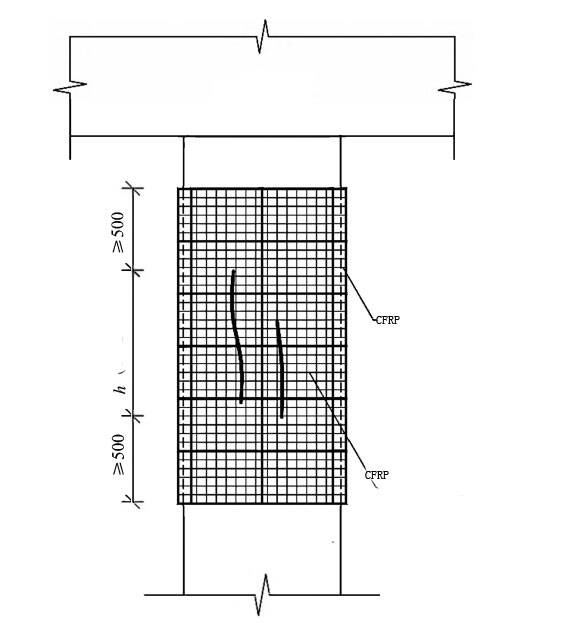

Carbon fiber for repairing longitudinal cracks of pile body

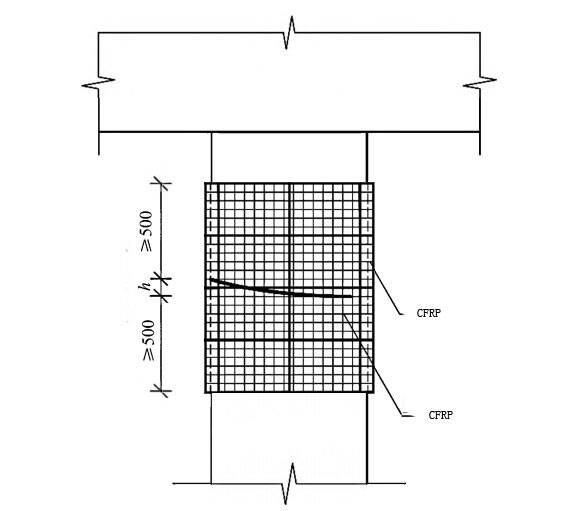

Carbon fiber for lateral crack repair of pile body

1) If the concrete at the top of the pile is damaged, first grouting to repair the damaged area, and then stick 3 to 4 layers of carbon fiber cloth circumferentially within the range of not less than 0.5 m from the top of the pile to the lower edge of the damaged area. If the pile body has vertical or horizontal cracks, first seal or grouting to repair the cracks, and then stick 3 to 4 layers of carbon fiber cloth vertically on each side of the pile foundation cracks. Then 2~3 layers of carbon fiber cloth are pasted circumferentially, and the pasting range is not less than 0.5 m above the top of the crack or not less than 0.5 m from the top of the pile to the bottom of the crack.

2) CFRP carbon fiber cloth performance index requirements: high-strength class I.

3) The key to the repair and reinforcement technology of pasting carbon fiber cloth is to ensure that the carbon fiber cloth and the pile foundation are firmly bonded to form a whole, so as to achieve the purpose of common stress, so as to give full play to the tensile properties of the carbon fiber cloth. In order to ensure the bonding effect, attention should be paid to the treatment of the base surface, the selection of adhesives and the operation of pasting.

4) The lap width between the upper and lower layers of the hoop wrapping carbon fiber cloth should not be less than 50mm, the extension length of the hoop cut-off point should not be less than 200mm, and the overlapping positions of each carbon fiber cloth should be staggered.

5) After the carbon fiber cloth is pasted, the outer surface can be sprayed with acrylic mortar of not less than 20mm, and coated with anti-corrosion paint to improve the durability of the material and reduce the maintenance cost in the later period.