Bridge Strengthening

Prestressed CFRP Strip

Bridge Strengthening Method - Prestressed CFRP Strip

Project Overview

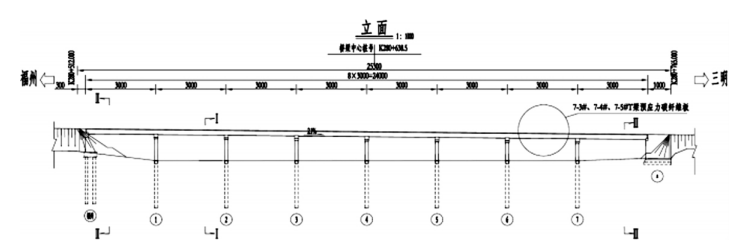

The total length of the bridge is 253m, and the bridge span is 8×30m. The design load of the bridge: steam-super 20, hanging 120. The upper structure adopts prestressed reinforced concrete quasi-continuous T-shaped beam, the type of support is rubber support, and the bridge deck is paved with asphalt concrete. The lower structure adopts the bridge abutment U platform to expand the foundation and the ribbed platform with pile foundation; the bridge pier adopts the column pier, and the upper and lower structures are shown in Figure 1.

Previous test results

Initial inspection results: In the regular inspection of the bridge in 2014, no vertical cracks, diagonal cracks, and transverse cracks at the bottom of the beam were found in the bridge.

Mid-term inspection results: During the regular inspection in July 2017, it was found that there were multiple exposed bars in the guardrail, multiple longitudinal cracks, diagonal cracks, and vertical cracks in the web of the T-shaped beam, and multiple horizontal and longitudinal cracks at the bottom of the beam, as shown in Figure 2. Shown. The final technical status assessment result is a three-category bridge.

The result of the later inspection was only 10 months from the regular inspection in July 2017 to the special inspection in May 2018, and the crack scale (fracture width) developed rapidly. Check again in July 2018, the crack scale (fracture width) developed rapidly, and new cracks were found, as shown in Figure 3. The thick line is the newly added cracks inspected in July 2018, and the thin line is the cracks inspected before May 2018.

Main beam reinforcement plan

Layout plan of carbon fiber board

In view of the seriousness of the main girder of the Sanjiban Bridge, a girder replacement plan was proposed. However, because the girder replacement requires a fully enclosed construction and the construction period is long, which has a great impact on the normal traffic of the expressway, the treatment plan is changed and reinforcement measures are adopted. . Now the 7-3#, 7-4#, and 7-5# beams are reinforced by the prestressed carbon fiber reinforcement technology with more obvious reinforcement effect, as shown in Figure 4.

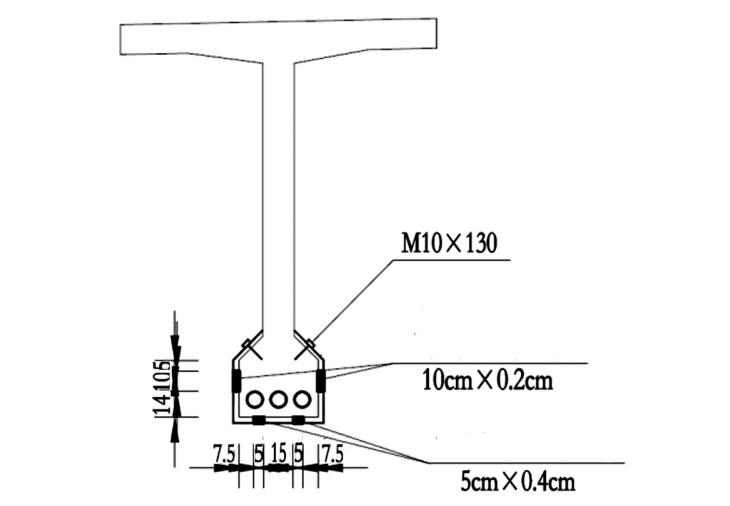

7-3#, 7-4#, 7-5# beams are reinforced concrete structures. According to the design requirements, one carbon fiber board with a width of 10 cm and a thickness of 0.2 cm is arranged on each side of the beam, and two carbon fiber boards with a width of 5 cm and a thickness of 0.4 cm are arranged at the bottom of the beam, as shown in Figure 5.